Durability and Materials of Automotive Connectors

Automotive connectors are key components that link various electrical systems within modern vehicles. These connectors facilitate communication between different parts of the vehicle, such as sensors, control units, lights, and more.

The primary purpose of automotive connectors is to provide a secure and reliable electrical connection between different vehicle components. These components can include anything from the engine control unit (ECU) to infotainment systems, lighting, sensors, and more.

For example, connectors are essential in systems like airbags, where they ensure that electrical signals are properly transmitted for the deployment mechanism. Similarly, connectors in lighting systems allow for consistent power to illuminate headlights and taillights.

Automotive connectors come in various forms, each designed for specific applications and environments. Some of the more common types of connectors used in vehicles include:

Wire-to-Wire Connectors: These are used to connect two or more wires to transmit electrical signals and power. They are typically used in wiring harnesses, which bundle wires together to distribute power throughout the vehicle.

Wire-to-Board Connectors: These connectors link wires to a circuit board. They are commonly used in automotive electronic systems where a connection between wires and a PCB (Printed Circuit Board) is needed, such as in the vehicle's infotainment or control systems.

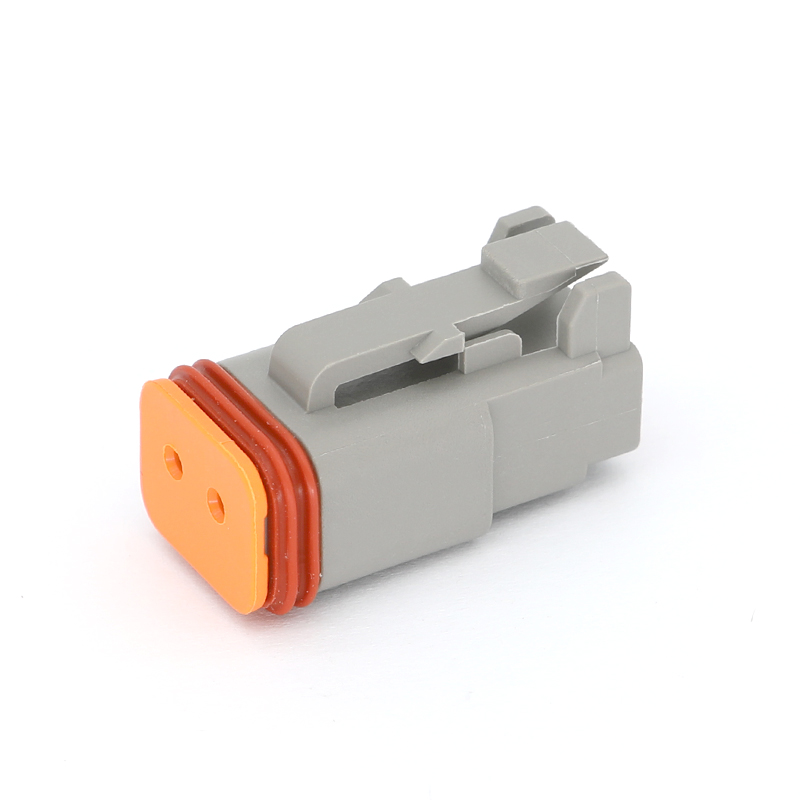

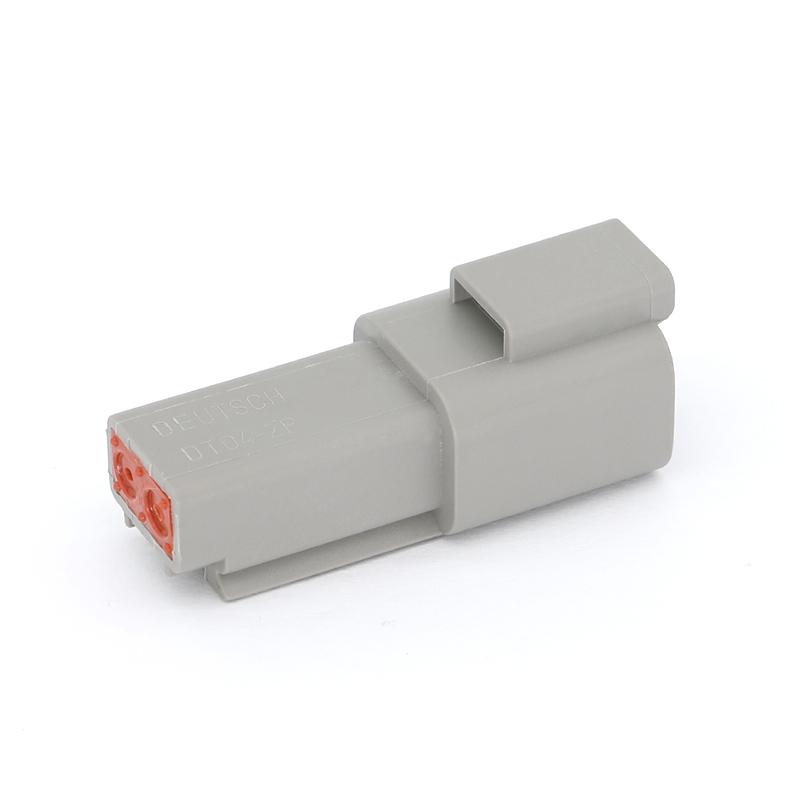

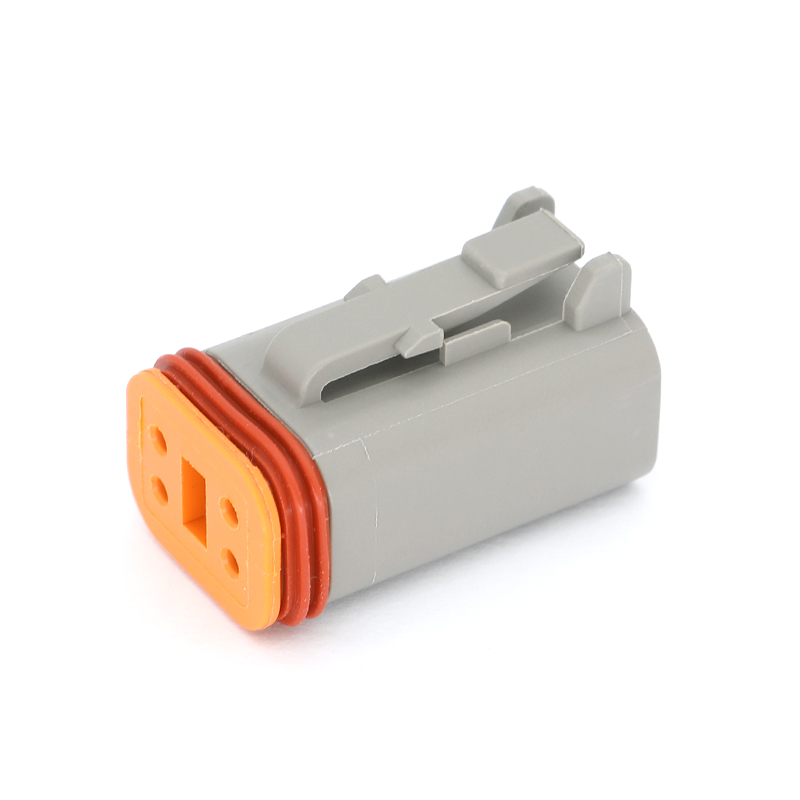

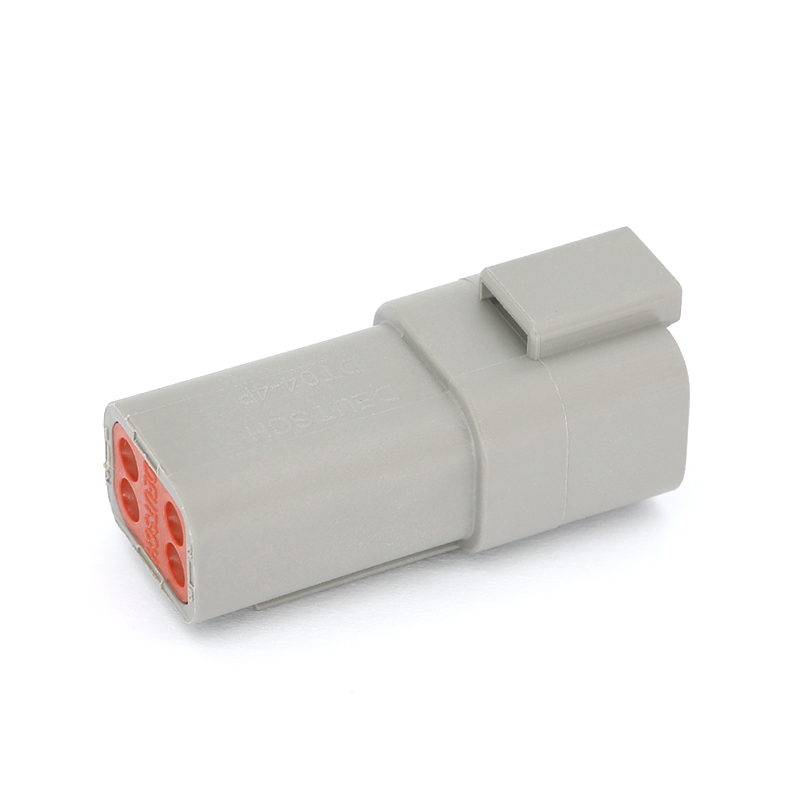

Circular Connectors: Circular connectors are often used in applications where the connection needs to be robust and resistant to environmental factors such as water, dirt, and vibrations. These connectors are commonly found in areas like engine compartments and undercarriages.

Flat Connectors: Flat connectors are used when space is a concern. These connectors are designed to fit in tight spaces and are often used in areas such as dashboards or compact engine spaces.

Automotive connectors must be able to withstand the challenging conditions that vehicles are exposed to, such as bad temperatures, moisture, and vibrations. For this reason, these connectors are typically made from high-quality materials such as thermoplastics and copper alloys. These materials offer durability and resistance to wear and tear, ensuring the connectors function effectively over time.

Additionally, connectors are often equipped with seals or other protective measures to prevent moisture, dirt, or debris from entering the connections. This is important because any disruption in the electrical signal or power could pilot system failure, which may impact vehicle performance or safety.

With the advancement of vehicle technologies, the role of automotive connectors is expanding. Electric vehicles (EVs) require connectors that can handle high voltage and power levels for their battery management systems and charging infrastructure. Similarly, the rise of autonomous vehicles has increased the demand for connectors that can transmit large amounts of data between sensors, cameras, and control units in real-time.

As vehicles continue to incorporate advanced safety and infotainment systems, the need for reliable, durable, and high-performance connectors will only continue to grow. Manufacturers are continuously developing new connectors to meet the demands of electric, hybrid, and autonomous vehicles, ensuring that these vehicles remain efficient, safe, and fully functional.

Automotive connectors are essential for the proper functioning of modern vehicles. They link various electrical systems and allow for smooth communication between components, ensuring the vehicle operates as intended. With advancements in electric and autonomous vehicle technologies, the demand for high-quality connectors is expected to rise, making them a fundamental aspect of future vehicle design and performance.

English

English русский

русский Español

Español عربى

عربى 简体中文

简体中文