In the rapidly evolving automotive industry, where technology and innovation are the driving forces behind progress, the role of a...

READ MOREProduct Series

- - Crimp Terminal

-

- PCB Connector

- - 1.0mm pitch Connector

- - 1.25mm pitch Connector

- - 1.5mm pitch Connector

- - 2.0mm pitch Connector

- - 2.5mm pitch Connector

- - 2.54mm pitch Connector

- - 3.0mm pitch Connector

- - 3.7mm pitch Connector

- - 3.96mm pitch Connector

- - 4.14mm pitch Connector

- - 4.2mm pitch Connector

- - 4.5mm pitch Connector

- - 5.0mm pitch Connector

- - 5.03mm pitch Connector

- - 5.08mm pitch Connector

- - 5.5mm pitch Connector

- - 6.2mm pitch Connector

- - 6.3mm pitch Connector

- - 6.7mm pitch Connector

-

- Auto Connector

- - 1 Pin Connector

- - 2 Pin Connector

- - 3 Pin Connector

- - 4 Pin Connector

- - 5 Pin Connector

- - 6 Pin Connector

- - 7 Pin Connector

- - 8 Pin Connector

- - 9 Pin Connector

- - 10 Pin Connector

- - 11 Pin Connector

- - 12 Pin Connector

- - 13 Pin Connector

- - 14 Pin Connector

- - 15 Pin Connector

- - 16 Pin Connector

- - 17 Pin-20 Pin Connector

- - 21 Pin-30 Pin Connector

- - 31 Pin-40 Pin Connector

- - 41 Pin-50 Pin Connector

- - 51 Pin-60 Pin Connector

- - Over 60 Pin Connector

-

- Wiring Harness

-

- New Energy Car Connector

- - Connector Components

- - Wiring Tools

Windshield Rubber Seal in China

Information to be updated

Rubber seals are integral components within connector assemblies, providing essential sealing properties to ensure good performance and longevity.

Definition and Composition of Rubber Seals:

Rubber seals, also known as gaskets or O-rings, are elastomeric components typically made from materials such as EPDM (ethylene propylene diene monomer), or NBR (nitrile butadiene rubber). These seals are designed to prevent leakage of fluids or gases between mating surfaces, thus maintaining a secure connection.

nice Sealing Property:

One of the key attributes of rubber seals is their nice sealing property. Through precise engineering and material selection, rubber seals create a tight barrier, effectively preventing the ingress or egress of liquids or gases. This feature is crucial for ensuring the integrity and reliability of connector systems in diverse environments.

High Temperature Loadability and Stability:

Our rubber seals exhibit temperature loadability and stability, making them suitable for applications subjected to elevated temperatures. Whether in automotive engines, industrial machinery, or electrical systems, these seals maintain their structural integrity and sealing effectiveness even under heat conditions.

Application in Various Industries:

Our high-quality rubber seals find widespread use across multiple industries, including automotive, motorcycle, and new energy vehicle sectors. Within these industries, rubber seals serve diverse functions, ranging from fluid containment in engine components to electrical insulation in battery systems.

Automotive Industry Application:

In the automotive industry, rubber seals play a critical role in sealing engine components, transmissions, and fuel systems. They withstand the rigors of engine operation, ensuring that fluids such as oil, coolant, and fuel remain contained within their respective circuits, thus contributing to the overall performance and longevity of vehicles.

Motorcycle Industry Application:

Rubber seals are indispensable in motorcycle manufacturing, where they are utilized in various subsystems such as suspension, braking, and fuel delivery systems. These seals provide reliable sealing solutions, safeguarding critical components against environmental contaminants and maintaining operational efficiency.

New Energy Vehicle (NEV) Industry Application:

With the rapid growth of the new energy vehicle sector, rubber seals are in high demand for applications in electric propulsion systems, battery packs, and charging infrastructure. Our seals offer performance in these environments, ensuring the safety and efficiency of NEV components.

Quality Standards and Assurance:

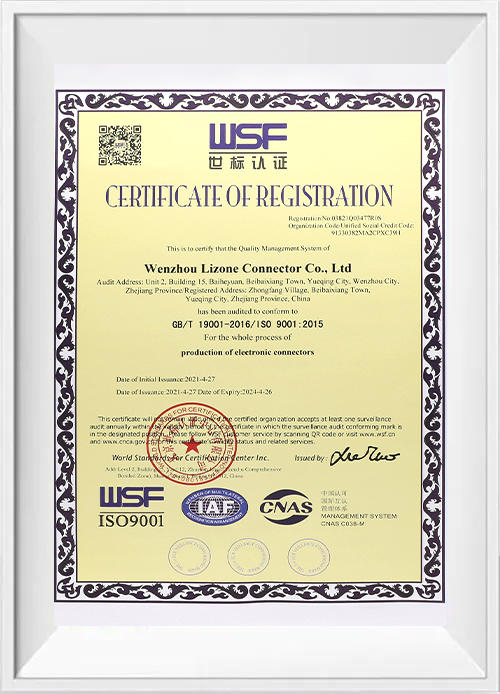

We adhere to stringent quality standards in the production of rubber seals, employing advanced manufacturing processes and rigorous testing protocols. Our commitment to quality ensures that each seal meets or exceeds industry specifications, delivering consistent performance and reliability.

Customization and Flexibility:

Recognizing the diverse requirements of our customers, we offer customization options for rubber seals to meet specific application needs. Whether it's variations in size, shape, or material composition, our engineering team works closely with clients to develop tailored solutions that optimize performance and efficiency in their unique environments.

Environmental Considerations:

In addition to their functional attributes, our rubber seals are designed with environmental considerations in mind. We prioritize the use of materials that are compliant with environmental regulations and strive to minimize the environmental footprint of our manufacturing processes. By employing sustainable practices, we ensure that our products contribute to a greener and more sustainable future.

Rubber seals represent indispensable components within connector systems, providing essential sealing functions across a wide range of industries. With their nice sealing properties, high temperature stability, and broad applicability, our rubber seals contribute to the efficiency, safety, and durability of various automotive, motorcycle, and new energy vehicle applications.

Who are we?

Wenzhou Lizone Connector Co., Ltd. is China Rubber Seal manufacturers and custom Rubber Seal factory, located in Yueqing City, Zhejiang Province, is the city with the earliest domestic market economy and the dynamic economic development. It is close to 104 National Highway and Yongtaiwen Expressway, Wenzhou Bridge. The North White Elephant exit is 5 kilometers away, and it is about 25 kilometers away from Wenzhou Airport and the railway station. The traffic is very convenient.

The company specializes in the production of various automotive, motorcycle electrical circuit connectors, connectors, connecting terminals, fuse boxes, fuses, wiring harnesses, lamp holders, with new product development and mold precision manufacturing for 20 years and with many domestic automotive wiring harnesses Factory supporting cooperation.

-

Industry experience

0+ -

Product

0+ -

Client

0+ -

Patent

0+

-

-

In the complex and dynamic world of automotive engineering, where precision and reliability are paramount, the role of 2 pin auto ...

READ MORE -

In today's increasingly interconnected world, electronic devices rely on a complex network of components to function efficiently a...

READ MORE -

In the intricate world of electronics, where devices are becoming increasingly complex and interconnected, the role of connectors ...

READ MORE

English

English русский

русский Español

Español عربى

عربى 简体中文

简体中文