In the vast and complex world of electronics, where sophisticated components and advanced technologies often take center stage, th...

READ MOREProduct Series

- - Crimp Terminal

-

- PCB Connector

- - 1.0mm pitch Connector

- - 1.25mm pitch Connector

- - 1.5mm pitch Connector

- - 2.0mm pitch Connector

- - 2.5mm pitch Connector

- - 2.54mm pitch Connector

- - 3.0mm pitch Connector

- - 3.7mm pitch Connector

- - 3.96mm pitch Connector

- - 4.14mm pitch Connector

- - 4.2mm pitch Connector

- - 4.5mm pitch Connector

- - 5.0mm pitch Connector

- - 5.03mm pitch Connector

- - 5.08mm pitch Connector

- - 5.5mm pitch Connector

- - 6.2mm pitch Connector

- - 6.3mm pitch Connector

- - 6.7mm pitch Connector

-

- Auto Connector

- - 1 Pin Connector

- - 2 Pin Connector

- - 3 Pin Connector

- - 4 Pin Connector

- - 5 Pin Connector

- - 6 Pin Connector

- - 7 Pin Connector

- - 8 Pin Connector

- - 9 Pin Connector

- - 10 Pin Connector

- - 11 Pin Connector

- - 12 Pin Connector

- - 13 Pin Connector

- - 14 Pin Connector

- - 15 Pin Connector

- - 16 Pin Connector

- - 17 Pin-20 Pin Connector

- - 21 Pin-30 Pin Connector

- - 31 Pin-40 Pin Connector

- - 41 Pin-50 Pin Connector

- - 51 Pin-60 Pin Connector

- - Over 60 Pin Connector

-

- Wiring Harness

-

- New Energy Car Connector

- - Connector Components

- - Wiring Tools

Crimp Terminal Kit Factory

Information to be updated

Tail clips & back caps are designed to enhance the performance and reliability of electrical connections. The primary purpose of tail clips is to securely fasten wires or cables to connectors, ensuring a stable and uninterrupted flow of electrical signals. Meanwhile, back caps serve as protective covers, shielding connectors from environmental elements such as water, dust, and debris. Together, these components contribute to the longevity and functionality of electrical systems in various industrial applications.

Strong Water-proof and Dust-proof Properties

One of the standout features of tail clips & back caps is their water-proof and dust-proof capabilities. Engineered using advanced materials and precision manufacturing processes, these components create a tight seal around connectors, effectively preventing moisture ingress and dust accumulation. This robust protection is crucial in environments where exposure to water and contaminants could compromise the integrity of electrical connections, ensuring good performance and reliability even in harsh conditions.

High Temperature Loadability and Stability

Tail clips & back caps exhibit temperature loadability and stability, making them ideal for applications where heat resistance is paramount. Engine compartments in vehicles, for instance, often experience high temperatures during operation. In such demanding environments, these components remain resilient and maintain their structural integrity, ensuring uninterrupted electrical conductivity and system performance. Their ability to withstand temperatures underscores their reliability and suitability for critical automotive and industrial applications.

High Strength, Good Toughness, and Durability

Characterized by high strength and good toughness, tail clips & back caps are engineered to endure mechanical stress and environmental factors without compromising performance. Their robust construction and durable materials enable them to withstand vibration, impact, and bending forces, ensuring secure electrical connections over prolonged periods. Whether installed in motorcycles, automobiles, or new energy vehicles, these components deliver reliability and longevity, reducing maintenance requirements and downtime.

Wide-ranging Applications

Tail clips & back caps find extensive use across diverse industries, owing to their versatility and reliability. In the automotive sector, they are integral to the electrical systems of vehicles, including traditional automobiles and emerging electric and hybrid models. Additionally, these components play crucial roles in motorcycles, where reliability and performance are paramount. Moreover, tail clips & back caps are indispensable in the field of new energy vehicles, supporting the efficient operation of electric drivetrains and energy management systems.

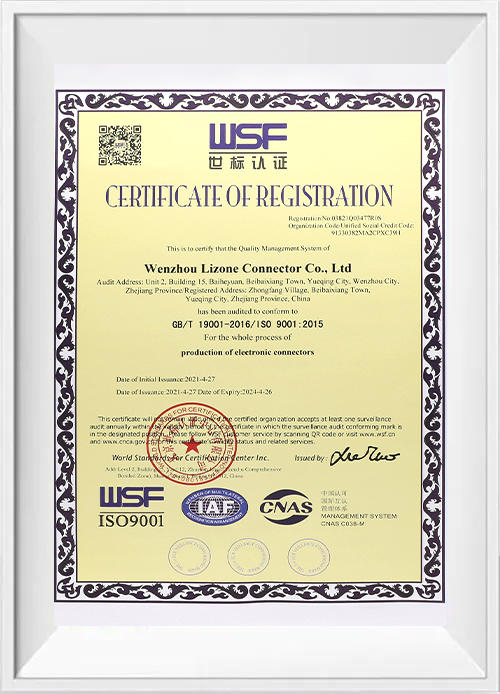

Quality Assurance

At every stage of production, stringent quality assurance measures are implemented to uphold the standards synonymous with our Tail Clips & Back Caps. From material sourcing to final inspection, each component undergoes thorough testing to ensure adherence to specifications and compliance with industry regulations. By prioritizing quality and reliability, we instill confidence in our customers, assuring them of the durability and performance consistency of our products in demanding operating environments.

In conclusion, Tail Clips & Back Caps are characterized by their robust waterproof and dustproof properties, high temperature load ability and stability, as well as strength and durability. Widely employed across diverse industries, these accessories serve as vital elements in ensuring secure and reliable connections in demanding environments. With their proven performance and versatile applications, Tail Clips & Back Caps continue to exemplify greatness in connectivity solutions, facilitating the seamless operation of various systems and equipment.

Who are we?

Wenzhou Lizone Connector Co., Ltd. is China Tail Clips & Back Caps manufacturers and custom Tail Clips & Back Caps factory, located in Yueqing City, Zhejiang Province, is the city with the earliest domestic market economy and the dynamic economic development. It is close to 104 National Highway and Yongtaiwen Expressway, Wenzhou Bridge. The North White Elephant exit is 5 kilometers away, and it is about 25 kilometers away from Wenzhou Airport and the railway station. The traffic is very convenient.

The company specializes in the production of various automotive, motorcycle electrical circuit connectors, connectors, connecting terminals, fuse boxes, fuses, wiring harnesses, lamp holders, with new product development and mold precision manufacturing for 20 years and with many domestic automotive wiring harnesses Factory supporting cooperation.

-

Industry experience

0+ -

Product

0+ -

Client

0+ -

Patent

0+

-

-

In the rapidly evolving automotive industry, where technology and innovation are the driving forces behind progress, the role of a...

READ MORE -

In the complex and dynamic world of automotive engineering, where precision and reliability are paramount, the role of 2 pin auto ...

READ MORE -

In today's increasingly interconnected world, electronic devices rely on a complex network of components to function efficiently a...

READ MORE

English

English русский

русский Español

Español عربى

عربى 简体中文

简体中文