Cheap Design High Quality Connector Components in China Maker In the intricate tapestry of electronic systems, connectors play a p...

READ MOREProduct Series

- - Crimp Terminal

-

- PCB Connector

- - 1.0mm pitch Connector

- - 1.25mm pitch Connector

- - 1.5mm pitch Connector

- - 2.0mm pitch Connector

- - 2.5mm pitch Connector

- - 2.54mm pitch Connector

- - 3.0mm pitch Connector

- - 3.7mm pitch Connector

- - 3.96mm pitch Connector

- - 4.14mm pitch Connector

- - 4.2mm pitch Connector

- - 4.5mm pitch Connector

- - 5.0mm pitch Connector

- - 5.03mm pitch Connector

- - 5.08mm pitch Connector

- - 5.5mm pitch Connector

- - 6.2mm pitch Connector

- - 6.3mm pitch Connector

- - 6.7mm pitch Connector

-

- Auto Connector

- - 1 Pin Connector

- - 2 Pin Connector

- - 3 Pin Connector

- - 4 Pin Connector

- - 5 Pin Connector

- - 6 Pin Connector

- - 7 Pin Connector

- - 8 Pin Connector

- - 9 Pin Connector

- - 10 Pin Connector

- - 11 Pin Connector

- - 12 Pin Connector

- - 13 Pin Connector

- - 14 Pin Connector

- - 15 Pin Connector

- - 16 Pin Connector

- - 17 Pin-20 Pin Connector

- - 21 Pin-30 Pin Connector

- - 31 Pin-40 Pin Connector

- - 41 Pin-50 Pin Connector

- - 51 Pin-60 Pin Connector

- - Over 60 Pin Connector

-

- Wiring Harness

-

- New Energy Car Connector

- - Connector Components

- - Wiring Tools

Cable Management Sleeve in China

Information to be updated

Wire sleeves are essential connector accessories used in various industries, including automotive, motorcycle, and new energy vehicle sectors. These sleeves serve a crucial role in organizing, protecting, and managing wires and cables, ensuring efficient and safe electrical connections.

Features and Benefits of Wire Sleeves:

Protection: Wire sleeves offer protection against abrasion, heat, chemicals, moisture, and other environmental hazards, reducing the risk of wire damage and electrical failures.

Insulation: They provide insulation to wires, preventing electrical shorts and ensuring reliable conductivity, even in challenging operating environments.

Flexibility: Wire sleeves come in various flexible designs, allowing them to conform to the shape and size of wires and cables, ensuring a snug fit and good protection.

Durability: Constructed from high-quality materials, wire sleeves exhibit nice durability and longevity, withstanding harsh conditions and prolonging the lifespan of electrical systems.

Ease of Installation: Many wire sleeves feature user-friendly designs that facilitate easy installation and removal, saving time and effort during maintenance and repairs.

Considerations for Selecting Wire Sleeves:

Temperature Rating: Choose wire sleeves with temperature ratings suitable for the operating conditions of the application, ensuring compatibility with temperature s encountered in automotive, motorcycle, or new energy vehicle environments.

Material Compatibility: Consider the compatibility of wire sleeve materials with the types of wires and cables being used to prevent chemical reactions or degradation that could compromise performance.

Size and Flexibility: Select wire sleeves that accommodate the size and shape of the wires and cables while providing sufficient flexibility to allow for movement and adjustments.

Environmental Protection: Assess the level of protection offered by wire sleeves against moisture, chemicals, UV radiation, and other environmental factors prevalent in the application environment.

Regulatory Compliance: Ensure that the chosen wire sleeves comply with relevant industry standards and regulations governing electrical components and systems to maintain safety and reliability.

Applications of Wire Sleeves:

Automotive Industry: Wire sleeves are extensively used in automotive applications to protect and manage wiring harnesses, ensuring reliable electrical connections in vehicles. They safeguard wires from vibrations, heat, and mechanical damage, enhancing the longevity and performance of automotive systems.

Motorcycle Industry: In motorcycles, wire sleeves play a vital role in securing and insulating electrical wiring, especially in high-temperature areas near the engine and exhaust. They prevent wire chafing, abrasion, and short circuits, contributing to the safety and durability of motorcycle electrical systems.

New Energy Vehicles: With the rise of electric and hybrid vehicles, the demand for wire sleeves has increased significantly. These vehicles require efficient cable management solutions to safeguard sensitive electrical components and ensure good performance. Wire sleeves provide insulation and protection against harsh operating conditions encountered in electric vehicles.

In conclusion, wire sleeves are indispensable connector accessories used across various industries, including automotive, motorcycle, and new energy vehicles. Their role in organizing, protecting, and managing wires and cables is critical to ensuring efficient and safe electrical connections in modern vehicles and machinery. With a diverse range of types and applications, wire sleeves offer numerous benefits, including protection, insulation, flexibility, durability, and ease of installation. When selecting wire sleeves, careful consideration of factors such as temperature rating, material compatibility, size, flexibility, environmental protection, and regulatory compliance is essential to ensure good performance and reliability in demanding operating conditions.

Who are we?

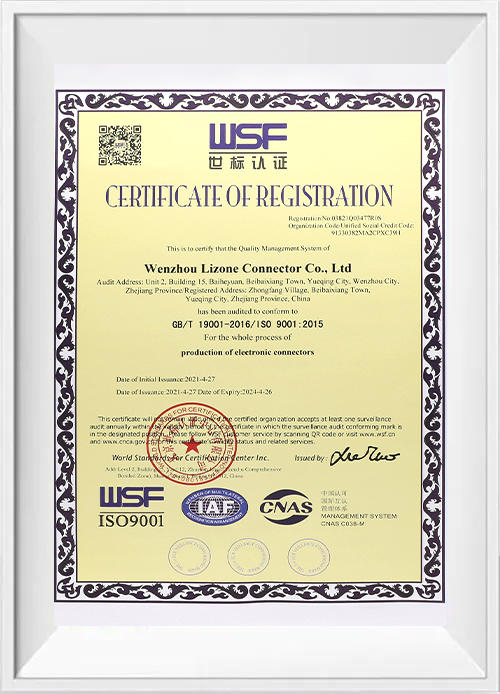

Wenzhou Lizone Connector Co., Ltd. is China Wire Sleeve manufacturers and custom Wire Sleeve factory, located in Yueqing City, Zhejiang Province, is the city with the earliest domestic market economy and the dynamic economic development. It is close to 104 National Highway and Yongtaiwen Expressway, Wenzhou Bridge. The North White Elephant exit is 5 kilometers away, and it is about 25 kilometers away from Wenzhou Airport and the railway station. The traffic is very convenient.

The company specializes in the production of various automotive, motorcycle electrical circuit connectors, connectors, connecting terminals, fuse boxes, fuses, wiring harnesses, lamp holders, with new product development and mold precision manufacturing for 20 years and with many domestic automotive wiring harnesses Factory supporting cooperation.

-

Industry experience

0+ -

Product

0+ -

Client

0+ -

Patent

0+

-

-

Design Sale Connector Components Manufacturing Supplier Maker In the vast landscape of electronics and electrical engineering, con...

READ MORE -

OEM ODM Connector Components Wholesaler Exporter Producer In the intricate world of electronics and electrical systems, connectors...

READ MORE -

OEM/ODM Wholesale Connector Components Manufacturer Factory Connector components are integral parts of electrical and electronic s...

READ MORE

English

English русский

русский Español

Español عربى

عربى 简体中文

简体中文