2 Pin Auto Electrical Connectors Ensure Vehicle Reliability

The modern automobile is a complex network of electrical and electronic systems, controlling everything from engine management and lighting to infotainment and safety features. At the heart of this vast network are countless electrical connections, with the humble 2 Pin Auto Electrical Connector serving as a fundamental and ubiquitous component. These connectors provide the critical interface for joining wires, enabling the transmission of power and signals between different vehicle modules, sensors, and actuators. The reliability, durability, and performance of these 2 Pin Auto Electrical Connectors are essential for ensuring vehicle functionality, safety, and longevity, making their design and manufacturing a specialized and vital segment within the automotive supply chain.

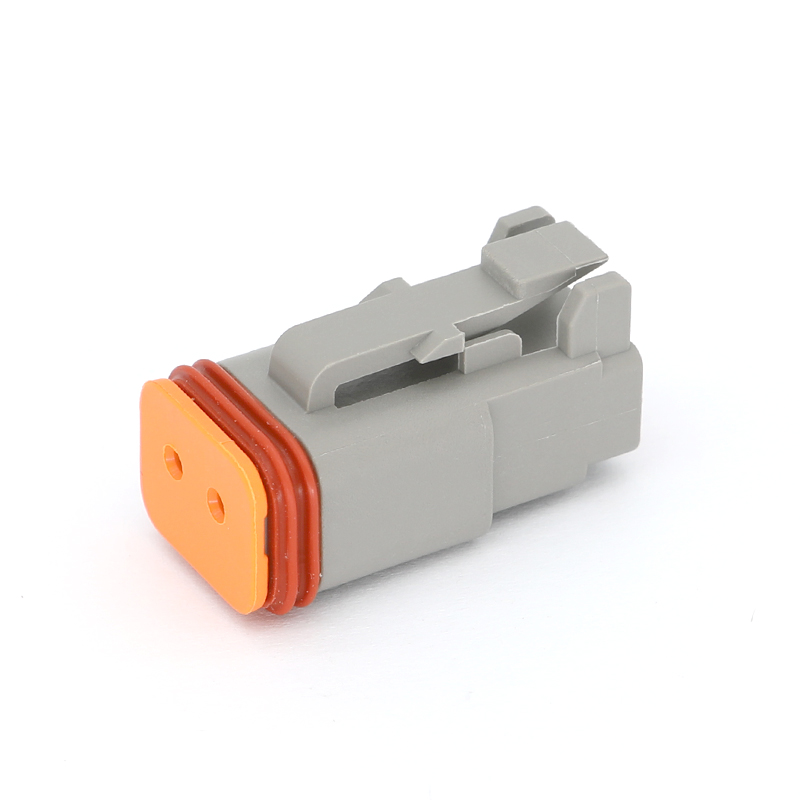

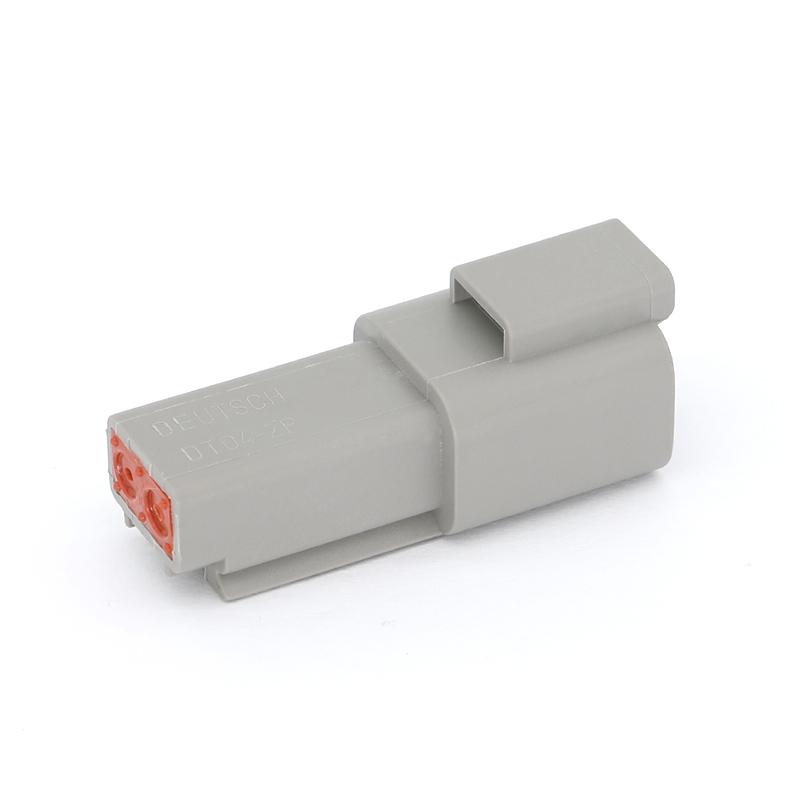

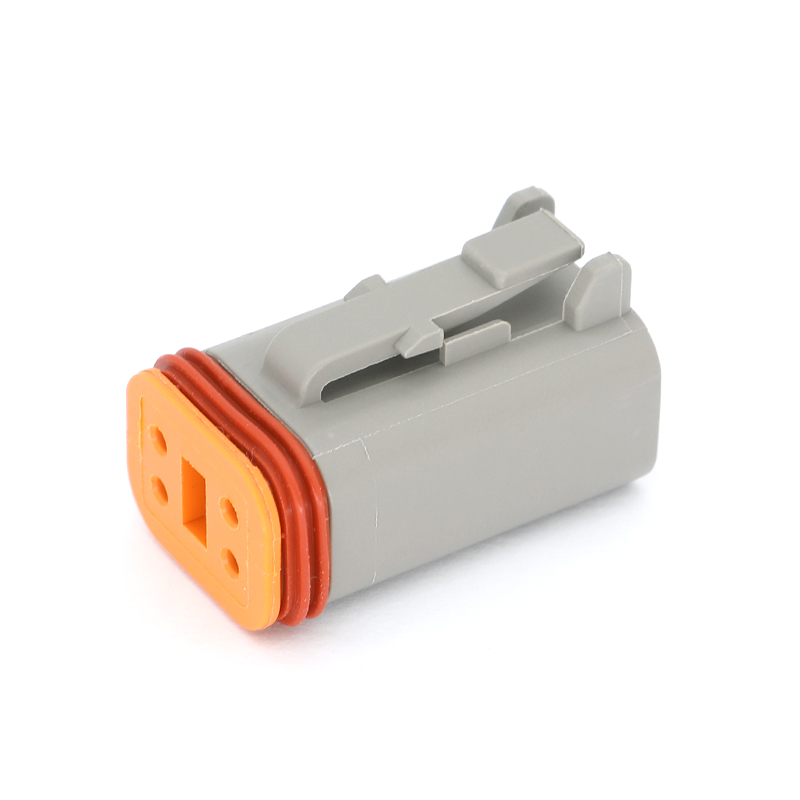

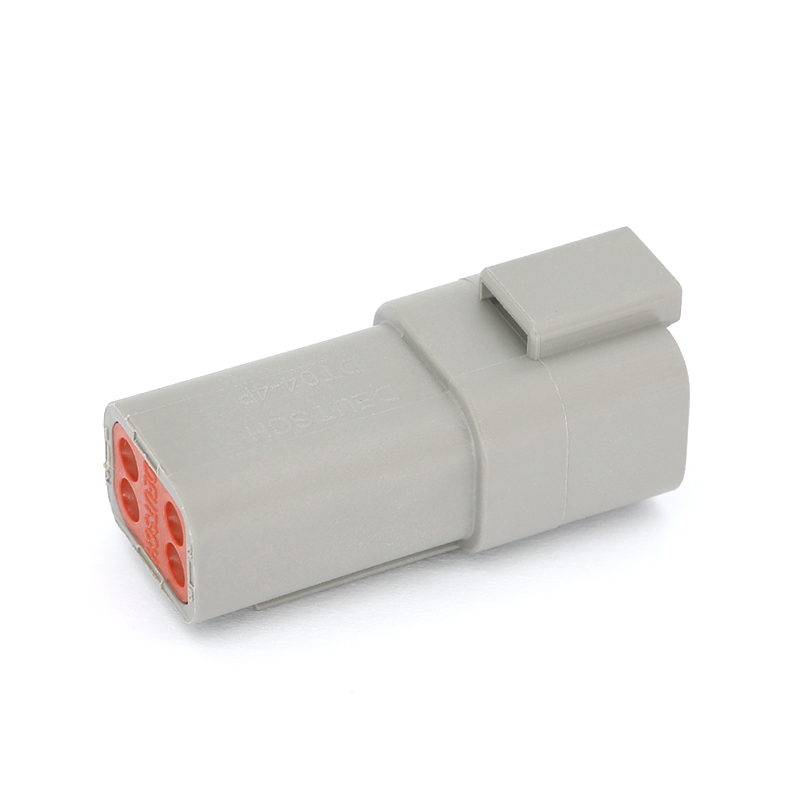

The design of a standard 2 Pin Auto Electrical Connector is deceptively simple, yet it embodies precise engineering to meet stringent automotive requirements. It consists of two primary parts: a housing (often made from high-temperature, chemical-resistant plastics like PBT or nylon) and the terminal contacts (typically made from brass, tinned copper, or other conductive alloys with plating for corrosion resistance). The housing provides physical protection, keying to prevent mis-mating, and a locking mechanism—often a simple but robust tab or clip—to ensure the connection remains secure against vibration, a constant challenge in the automotive environment. The terminal contacts are designed to create a gas-tight, low-resistance electrical joint when mated, which is crucial for consistent performance and preventing voltage drops or intermittent faults.

The application of 2 Pin Auto Electrical Connectors within a vehicle is extensive and varied. They are commonly used for lower-current applications where a simple, reliable two-wire connection is needed. Typical uses include connections for various sensors (e.g., temperature, speed, or position sensors), lighting units (such as side markers or interior lights), small motors (for power windows or mirrors), switches, and many under-dash or interior trim components. Their simplicity makes them cost-effective and easy to install on assembly lines, while their standardized designs allow for serviceability and repair in aftermarket settings. The widespread deployment of 2 Pin Auto Electrical Connectors underscores their role as the foundational building blocks of a vehicle's electrical architecture.

The evolution of automotive technology is driving innovation in the design and specification of 2 Pin Auto Electrical Connectors. As vehicles incorporate more electronics and transition toward higher-voltage systems like 48V architecture or full electric powertrains, even simple connectors must adapt. There is a growing emphasis on miniaturization, allowing more connections in tighter spaces, and on materials that can withstand higher continuous temperatures, especially in under-hood applications near engines or exhaust systems. Sealing is another critical area; many modern 2 Pin Auto Electrical Connectors incorporate rubber grommets or integrated seals to achieve an Ingress Protection (IP) rating, safeguarding the connection from moisture, dust, and fluids that could cause corrosion or short circuits.

The future of 2 Pin Auto Electrical Connectors will be influenced by the trends of vehicle electrification, autonomy, and connectivity. While their basic function remains, they will be expected to handle slightly different loads and coexist in environments with more electromagnetic interference. The push for increased automation in vehicle assembly may also influence connector design for easier robotic handling. Despite the increasing complexity of vehicles, the fundamental requirement for a reliable, two-wire connection ensures that the 2 Pin Auto Electrical Connector will remain an indispensable component, continuously refined to meet the evolving demands of safety, performance, and manufacturability in the automotive industry of tomorrow.

English

English русский

русский Español

Español عربى

عربى 简体中文

简体中文