10 Pin Connector Manages Complex System Integration

In the realm of electronics and electromechanical systems, where the density of functionality within devices continues to increase, the 10 pin connector has emerged as a vital interface for managing complex interconnection requirements. This component, featuring ten distinct electrical contacts within a single housing, is engineered to streamline the integration of multiple power lines and signal pathways. The design of the 10 pin connector addresses the need for organized, reliable, and space-efficient connectivity in applications ranging from industrial controls and telecommunications equipment to sophisticated consumer devices and medical instrumentation.

The fundamental advantage of a 10 pin connector lies in its capacity to consolidate numerous electrical connections. By providing ten individual pins, it can simultaneously carry several different voltage rails, dedicated ground lines, and multiple data or control signals—such as serial communication lines (UART, SPI, I2C), analog sensor inputs, or digital control outputs. This consolidation reduces the clutter and potential points of failure associated with using multiple simpler connectors. A well-designed 10 pin connector simplifies the assembly process, improves serviceability by allowing entire modules to be disconnected at once, and enhances the overall reliability of the system by small loose wiring.

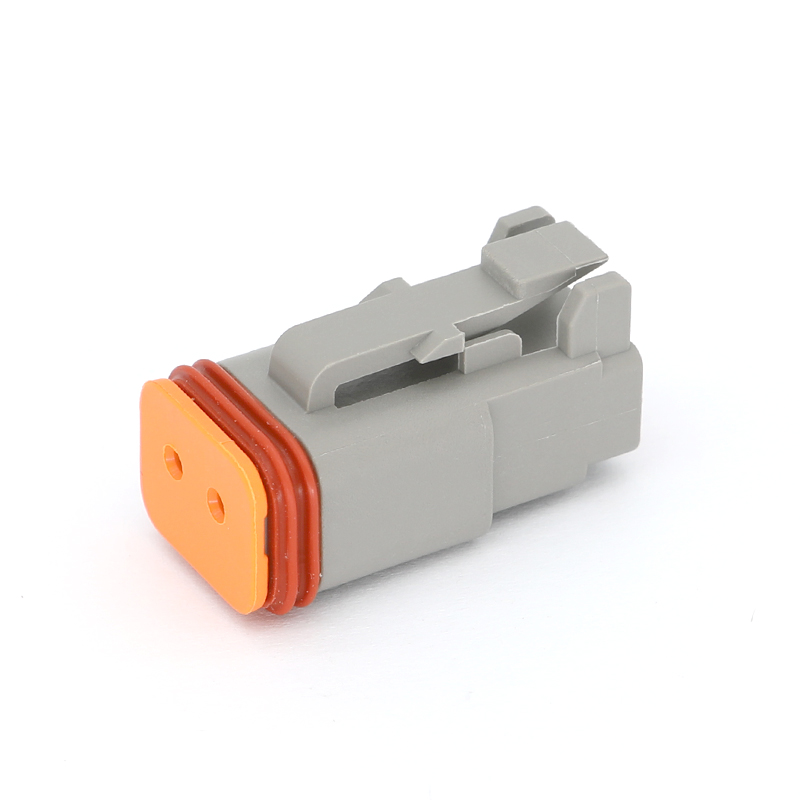

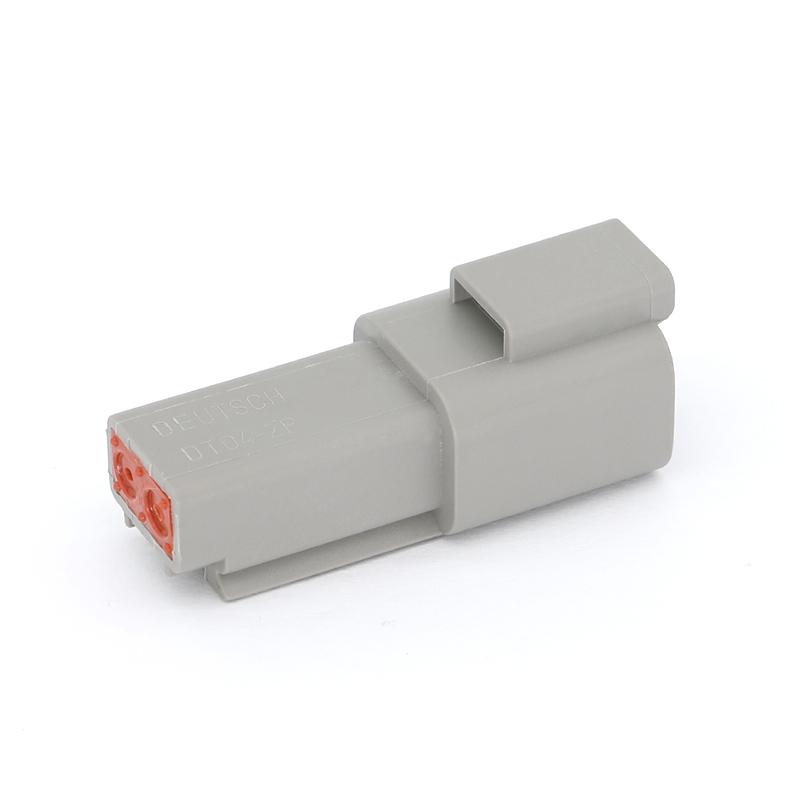

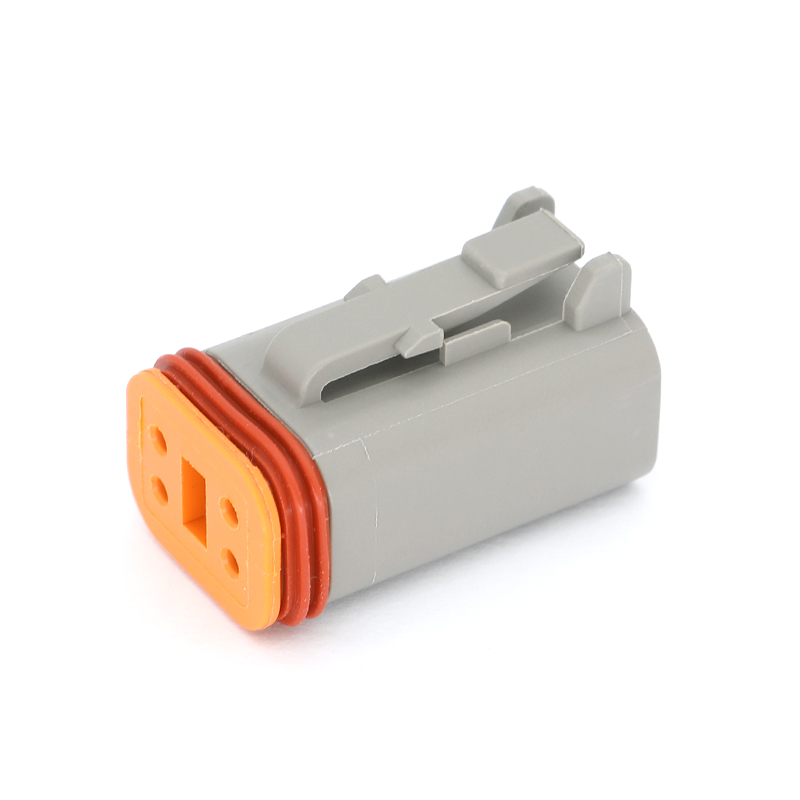

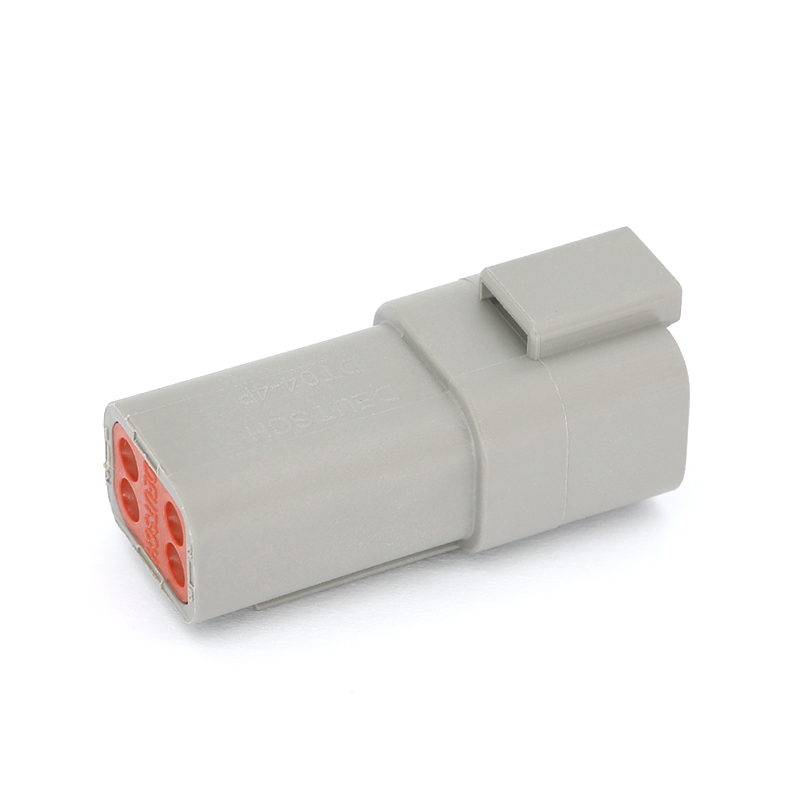

Robustness and precision are critical in the design and manufacture of a reliable 10 pin connector. The housing is typically molded from durable, often glass-filled, thermoplastic to provide mechanical strength and dimensional stability. The contacts, usually made from phosphor bronze or brass, are precisely stamped and formed, then plated with materials like gold over nickel or selective tin to ensure outstanding conductivity, low contact resistance, and resistance to corrosion over thousands of mating cycles. A secure latching mechanism—whether a simple friction lock, a screw-lock system, or a positive-action latch—is essential to maintain connection integrity in environments subject to vibration or incidental movement, preventing signal interruption or power loss.

The application of the 10 pin connector is diverse, reflecting its role as a versatile building block for system integration. In industrial automation, a 10 pin connector might be used to link a programmable logic controller (PLC) to a remote I/O module, carrying power, digital I/O signals, and communication lines. Within a piece of medical diagnostic equipment, it could connect a display panel or a sensor array to the main processing unit. In data and telecommunications, it is commonly found interconnecting boards within routers or switches, and in consumer electronics, it can serve as an internal harness for complex subsystems like a laptop's motherboard-to-display assembly.

The evolution of the 10 pin connector is influenced by trends toward miniaturization, higher data speeds, and increased power delivery within the same footprint. Future designs may incorporate advanced contact geometries to support higher-frequency signals or optimized power pins capable of carrying more current. The integration of shielding for electromagnetic compatibility (EMC) within the connector body is another area of development, especially for sensitive applications. As electronic systems grow more compact and multifunctional, the 10 pin connector will continue to adapt, remaining a fundamental and reliable solution for elegantly managing the intricate web of connections that power and control modern technology, effectively serving as a centralized nexus for both data and electrical power.

English

English русский

русский Español

Español عربى

عربى 简体中文

简体中文