6 Pin Auto Connector Powers Modern Vehicle Electronics

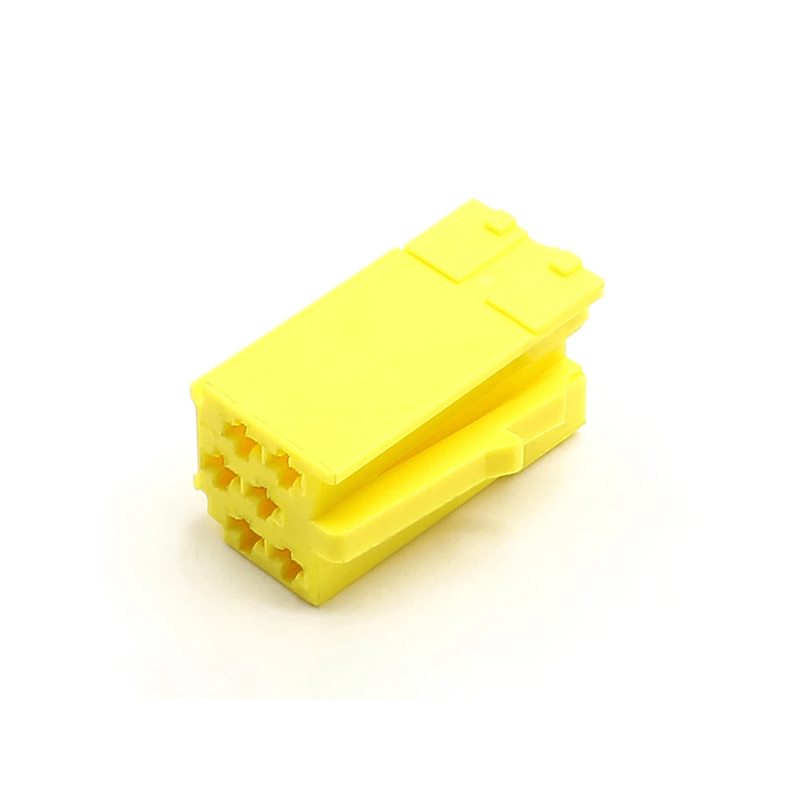

Within the complex electrical architecture of modern vehicles, a specific component plays a pivotal role in ensuring reliable communication and power delivery between various subsystems: the 6 pin auto connector. This specialized electrical interface, engineered to meet the rigorous demands of the automotive environment, provides a robust and secure connection for an array of sensors, actuators, and control modules. Its design balances the need for multiple electrical pathways with the imperative of durability, making the 6 pin auto connector a critical yet often unseen enabler of vehicle functionality, safety, and performance.

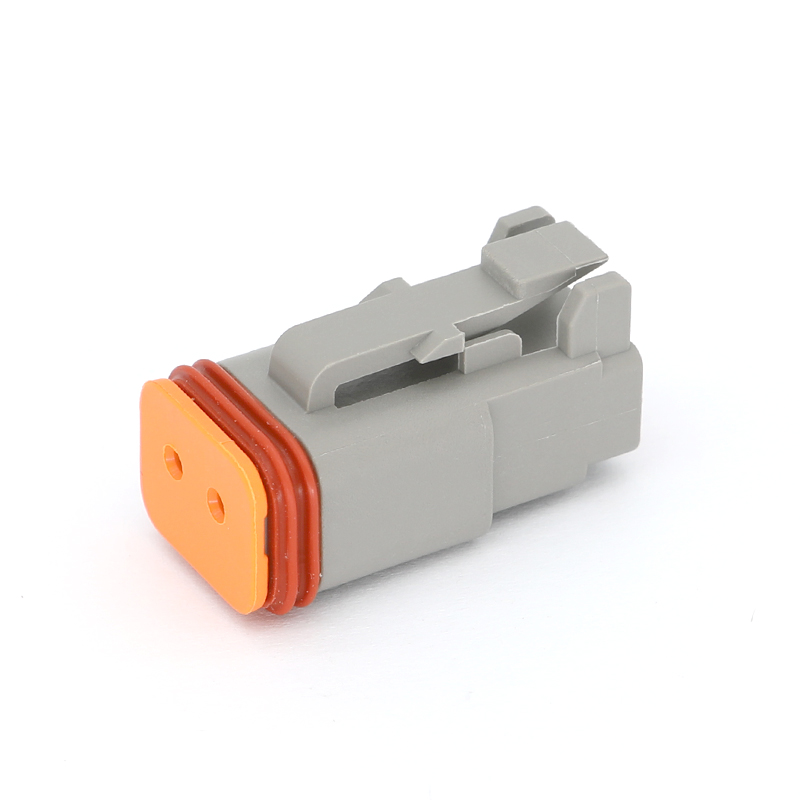

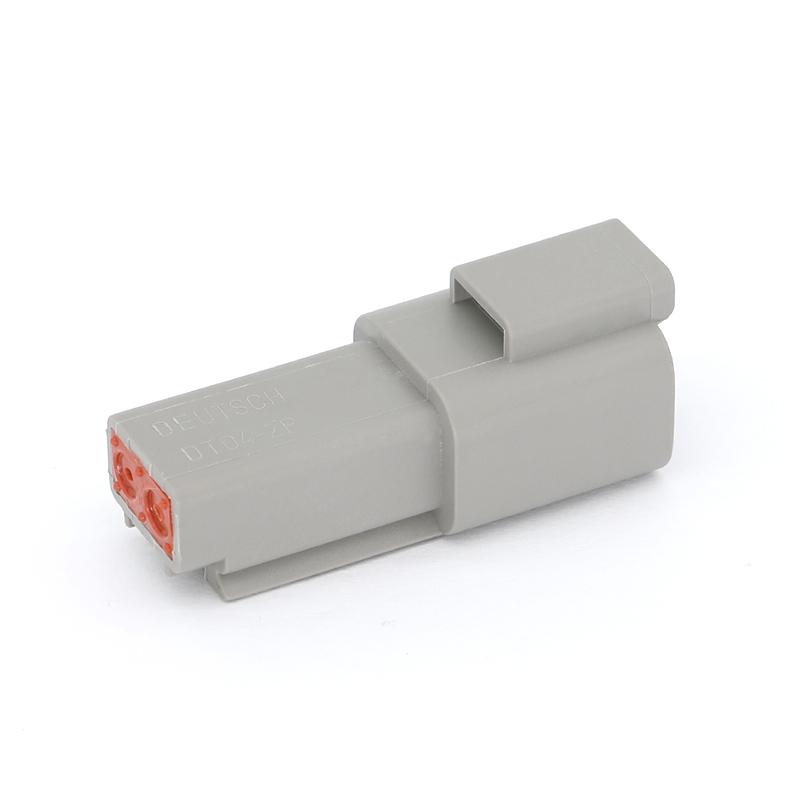

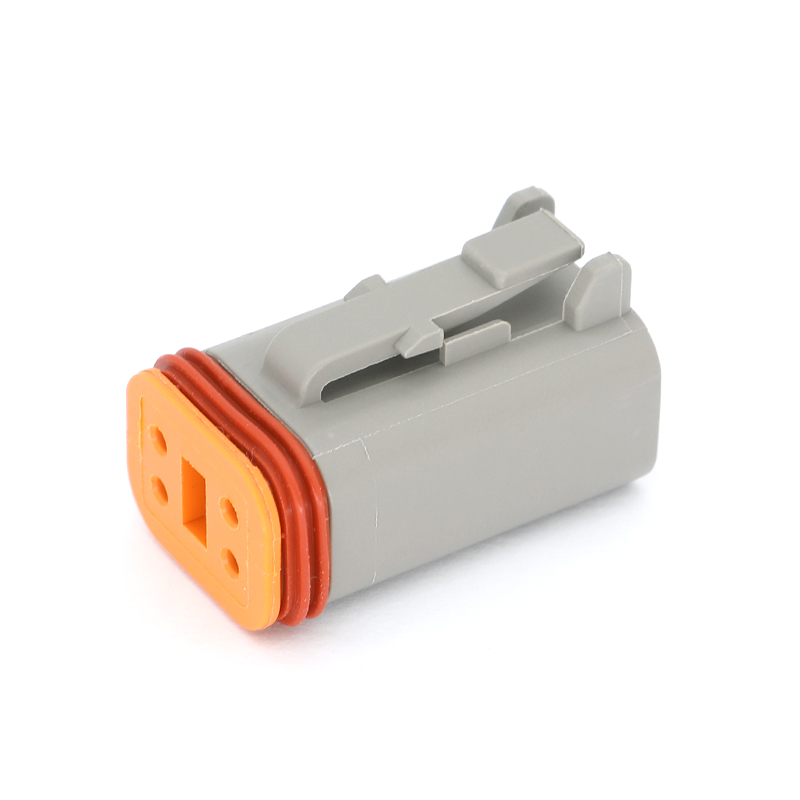

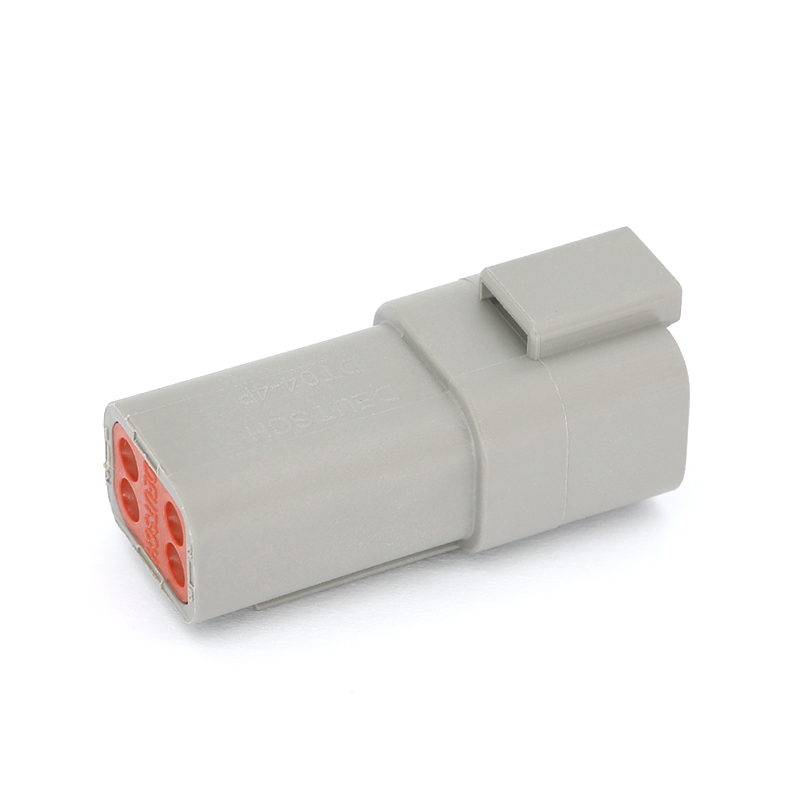

The fundamental purpose of a 6 pin auto connector is to create a sealed, vibration-resistant link capable of carrying power, ground, and multiple signal lines. The six individual pins within a single housing allow for a more complex set of electrical functions than simpler connectors. This configuration is commonly employed for components that require both operational power and bidirectional data communication, such as environmental sensors, lighting control units, or small electric motors. By consolidating these connections into one 6 pin auto connector, wiring harnesses become more organized, assembly is streamlined, and the potential for loose or incorrect wiring is significantly reduced, enhancing overall system reliability.

A defining characteristic of the automotive-grade 6 pin auto connector is its engineered resilience. Automotive applications subject electrical components to harsh conditions, including bad temperature fluctuations, exposure to moisture, chemicals like oil and brake fluid, and constant vibration. To withstand this environment, a high-quality 6 pin auto connector features an IP-rated (Ingress Protection) sealed housing, often made from high-temperature resistant thermoplastics. Crucially, it incorporates a sealing grommet and individual wire seals that prevent the ingress of water and contaminants, which could cause corrosion and electrical failure. The connector's latching mechanism is designed for a positive, audible click upon mating, ensuring a secure connection that will not loosen over the vehicle's lifetime.

Standardization and polarization are also key aspects of the 6 pin auto connector's design. While specific form factors vary by manufacturer and application, many follow broad industry guidelines for pin spacing and basic dimensions. More importantly, every 6 pin auto connector is meticulously polarized. This means the housing and terminal shapes are designed in a way that makes it physically impossible to mate the connector incorrectly. This foolproofing is essential in the high-volume, fast-paced environment of vehicle assembly and prevents catastrophic miswiring that could damage sensitive electronic control units (ECUs).

The evolution of the 6 pin auto connector is intrinsically linked to the automotive industry's shift toward electrification and increased data bandwidth. While the basic six-pin, sealed format remains highly relevant, the electrical performance requirements are rising. Future iterations may need to support higher data rates for sensor signals or handle slightly increased power for new actuators, all within the same compact, ruggedized form factor. Furthermore, the push for automated assembly will continue to drive designs that are easier for robots to handle and mate reliably. As vehicles incorporate more electronic content, the humble, robust 6 pin auto connector will remain an indispensable component, quietly ensuring the integrity of the electrical signals that keep modern automobiles functioning safely and efficiently.

English

English русский

русский Español

Español عربى

عربى 简体中文

简体中文