4 Pin Connector Facilitates Versatile Power and Data Links

In the intricate ecosystem of electronic and electromechanical systems, a specific interface plays a crucial role in enabling reliable and multi-functional connections: the 4 pin connector. This compact and standardized component, featuring four distinct electrical contacts, is engineered to transmit both power and multiple signal lines within a single, unified housing. Its design balances simplicity with functionality, making the 4 pin connector a prevalent and trusted solution across diverse industries, from consumer electronics and computing to industrial automation and automotive applications.

The fundamental purpose of a 4 pin connector is to establish a secure, detachable link that can handle more complex electrical requirements than a basic two-wire connection. The four individual pins allow for separate pathways, which are commonly allocated for distinct functions. A typical configuration might dedicate two pins for power (positive and negative) and the remaining two for differential data signals or for separate control and feedback lines. This multi-channel capability within a single 4 pin connector simplifies wiring harnesses, reduces installation space, and improves system reliability by small the number of individual connections required.

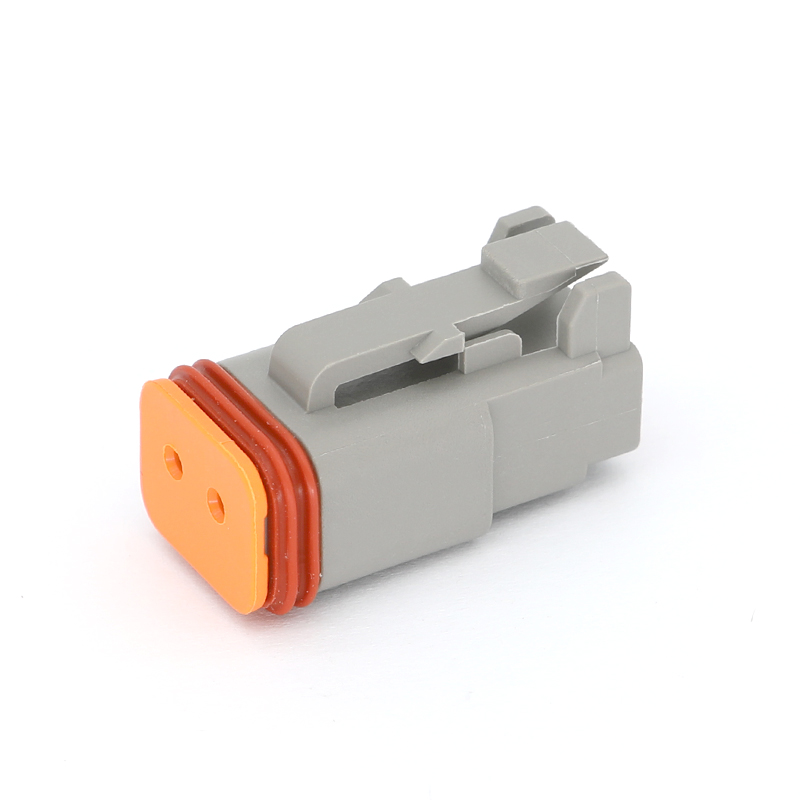

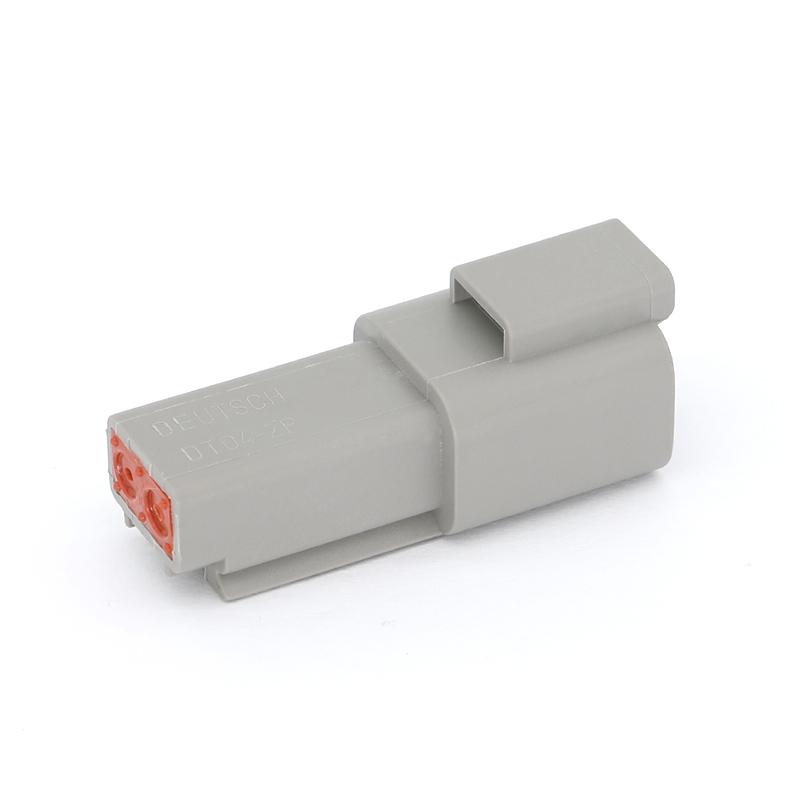

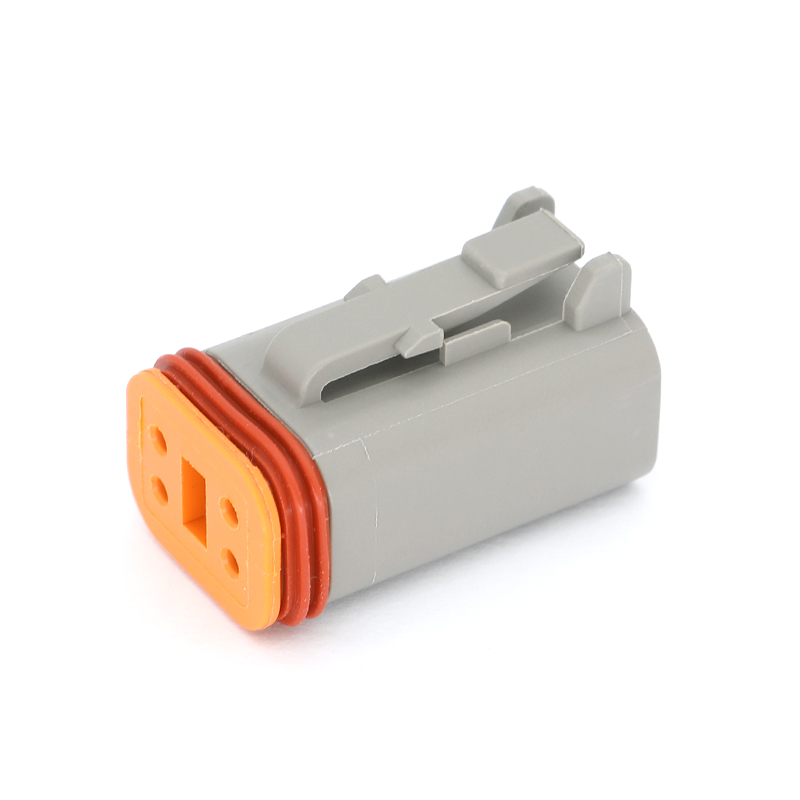

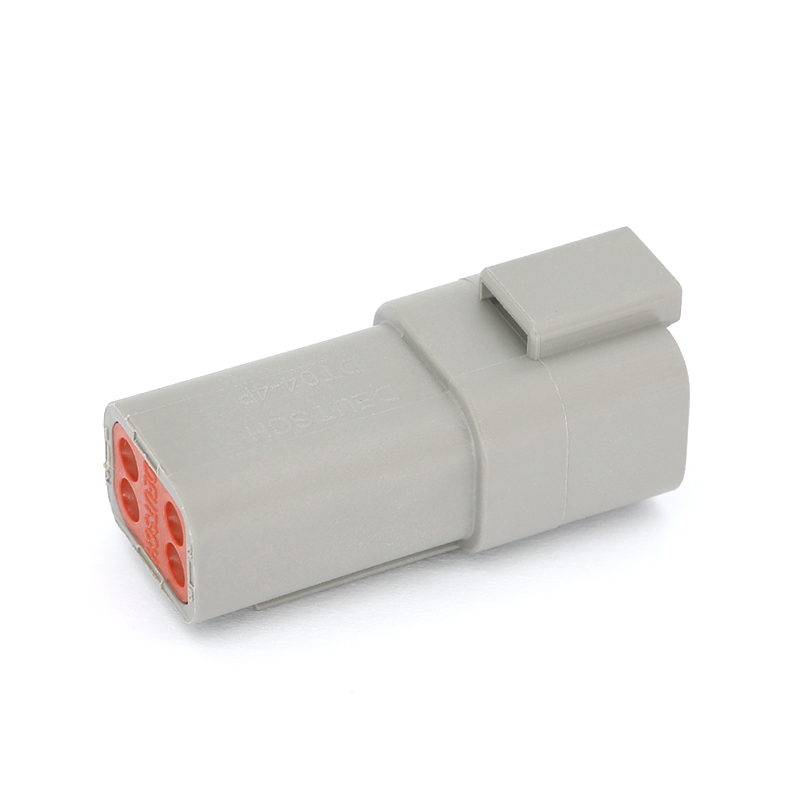

Standardization and keying are vital aspects of the 4 pin connector's widespread adoption. Many 4 pin connector families adhere to internationally recognized specifications that define the physical dimensions, pin spacing, current ratings, and mating sequences. This ensures interoperability between components from different manufacturers. Furthermore, 4 pin connector designs incorporate mechanical keying features—such as asymmetrical housings, polarized shapes, or specific latch positions—that prevent incorrect mating. This safeguards against potential damage from reversed power polarity or crossed signal lines, a critical feature for both user safety and equipment protection.

The application spectrum for the 4 pin connector is remarkably broad, underscoring its versatility. In personal computing, it is a standard interface for powering and controlling internal cooling fans, where the four pins manage power, ground, a tachometer signal (RPM feedback), and a pulse-width modulation (PWM) input for speed control. In consumer electronics, 4 pin connectors are often found in proprietary power adapters for laptops and monitors, carrying higher current alongside identification or communication signals. The automotive industry utilizes ruggedized 4 pin connectors for sensors, lighting modules, and in-vehicle accessories, where they must withstand vibration, temperature bads, and exposure to fluids.

Material science and engineering precision directly influence the performance and longevity of a 4 pin connector. High-quality versions utilize durable thermoplastic housings with good chemical resistance. The contacts are typically made from brass or phosphor bronze and plated with gold over nickel or tin to ensure outstanding conductivity, low contact resistance, and corrosion prevention. Robust locking mechanisms, such as snap-fit latches or screw locks, provide a secure physical connection that resists accidental disconnection in dynamic environments. These design choices ensure that a reliable 4 pin connector can maintain signal integrity and power delivery over thousands of mating cycles.

The evolution of the 4 pin connector is aligned with trends toward miniaturization, higher data rates, and increased power density. While the basic four-pin concept remains sound, advancements focus on improving the electrical performance of each pin. As systems become more integrated and intelligent, the dependable and adaptable 4 pin connector is poised to continue serving as a fundamental building block, efficiently bridging power and data in an ever-growing array of connected devices.

English

English русский

русский Español

Español عربى

عربى 简体中文

简体中文