2-Pin Auto Connectors: Essential Electrical Links

In the ever-evolving landscape of automotive technology, where innovation often focuses on high-profile advancements like battery efficiency or autonomous driving systems, a fundamental component continues to play a critical and unsung role: the 2-pin auto electrical connector. These small, seemingly simple devices remain the essential building blocks for a vast array of electrical circuits within modern vehicles, ensuring reliable performance and safety across numerous applications.

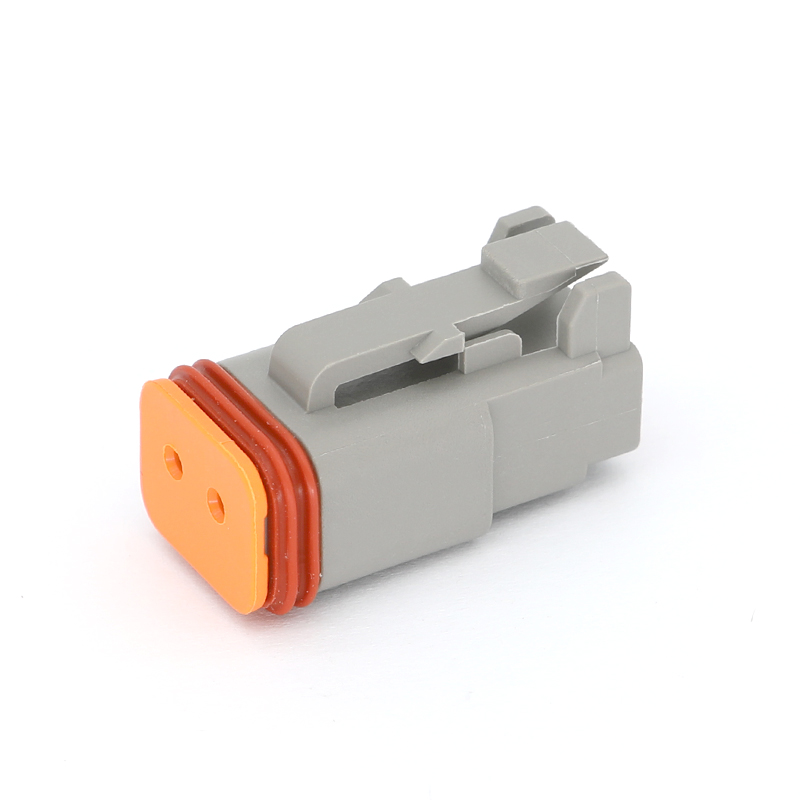

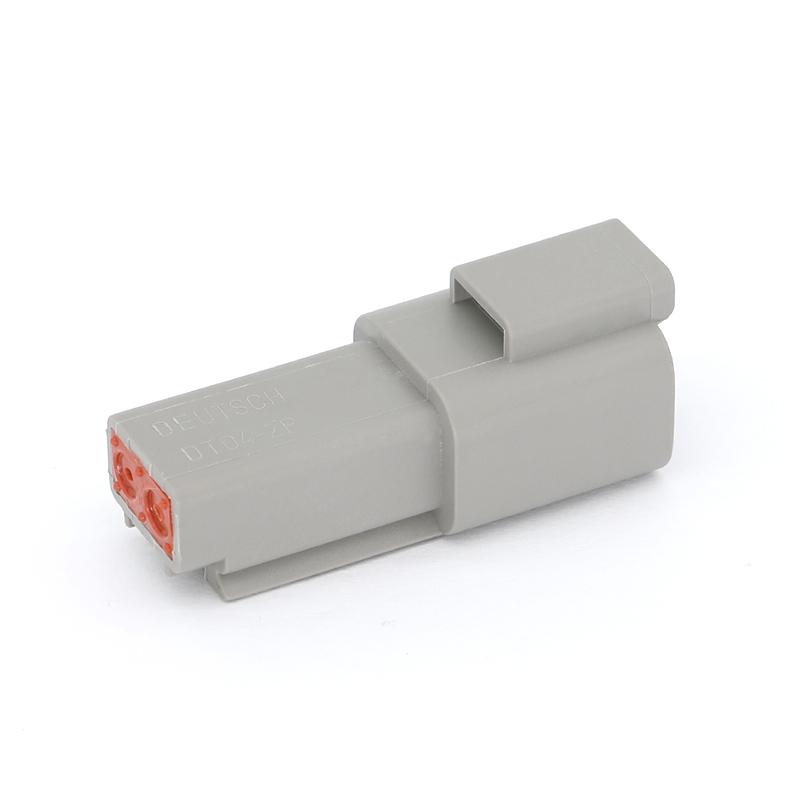

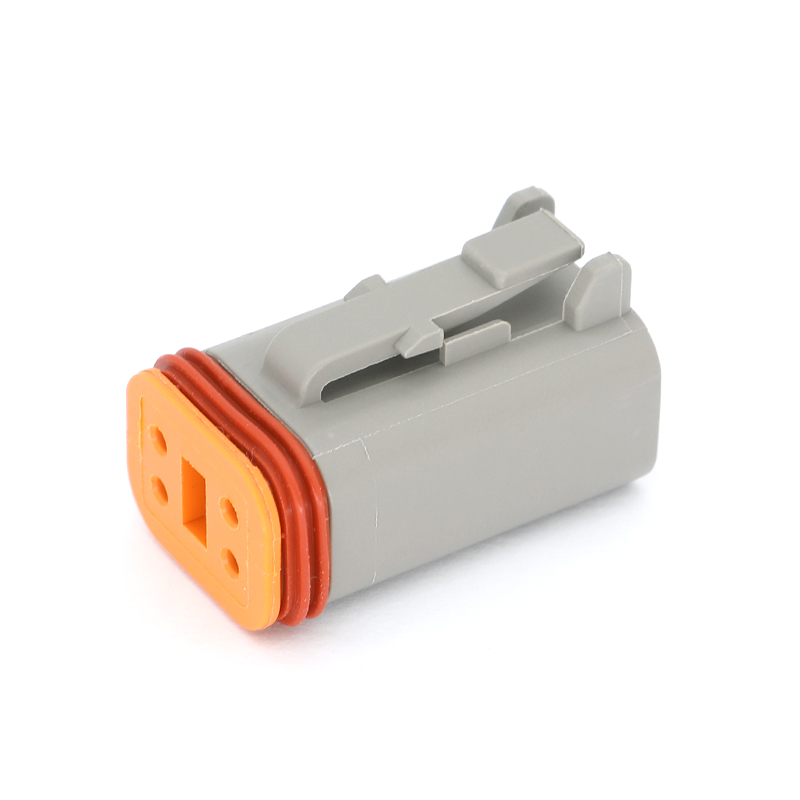

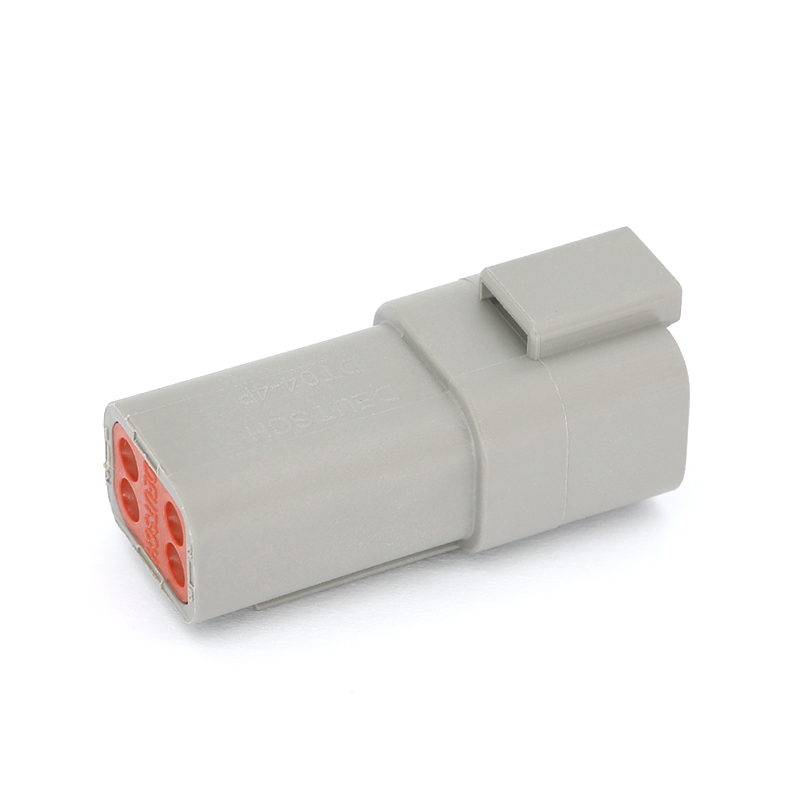

The primary function of a 2-pin auto electrical connector is to create a secure and detachable interface for electrical current. One pin serves as the positive terminal, while the other acts as the negative or ground terminal, completing the circuit. This straightforward design is its greatest strength, providing a versatile and cost-effective solution for a multitude of low-current applications. From powering interior lighting and dashboard indicators to connecting sensors and activating small motors, these connectors are ubiquitous. Their reliability is important for the consistent operation of everyday features, such as power window switches, audio system components, and various comfort controls. The design and manufacturing of these components prioritize secure mating and environmental resistance. Many are equipped with sealing grommets and robust housing materials to protect against moisture, dust, and vibration, which are common challenges in the automotive environment. This focus on durability helps prevent electrical failures that could cause malfunctions.

The materials used in manufacturing these connectors are selected for their electrical and mechanical properties. The pins are typically made from conductive metals such as brass or copper, often plated with tin or gold to enhance conductivity and resist corrosion. The outer housing is usually constructed from durable thermoplastics, which provide insulation and physical protection while withstanding the temperature variations experienced inside a vehicle. The installation and serviceability of automotive systems are greatly aided by the use of these standardized connectors. They allow for modular assembly during production and make subsequent repairs or replacements more straightforward for technicians. A faulty component can be easily disconnected and swapped out without the need for complex rewiring, reducing labor time and potential errors. This plug-and-play approach is a foundational element of modern automotive repair and manufacturing processes.

Looking forward, the role of the 2-pin connector is adapting to new trends. As vehicles incorporate more sophisticated electronics and driver-assistance features, the demand for reliable, point-to-point connections continues. While data-intensive systems require more complex connectors, the fundamental power and simple signal tasks handled by 2-pin versions remain in consistent demand. They are finding new applications in emerging areas, such as connectivity modules for telematics and additional sensors that enhance vehicle awareness and functionality. The ongoing development in the sector focuses on refining these established components, making them even more compact, resilient, and cost-efficient to meet the requirements of next-generation vehicle platforms.

The 2-pin auto electrical connector stands as a testament to the idea that not all important components need to be technologically complex. Its simple, effective, and reliable design has made it an indispensable part of the automotive electrical ecosystem. As the industry continues its shift towards electrification and digitalization, this fundamental component will continue to provide the essential electrical links that power a wide range of vehicle functions, solidifying its position as a key enabler of modern mobility.

English

English русский

русский Español

Español عربى

عربى 简体中文

简体中文