8 Pin Connector Powers Modern Device Systems

In the intricate world of modern electronics, the demand for components that can handle multiple functions within a compact footprint is greater than ever. The 8 pin connector has firmly established itself as a fundamental solution to this challenge, serving as a versatile and reliable interface in a vast array of devices. This component represents a significant evolution from its predecessors, offering a balanced combination of capacity, functionality, and physical practicality that meets the complex needs of contemporary system design. Its widespread adoption across industries highlights its critical role in enabling advanced features and streamlined assembly processes.

The primary advantage of the 8 pin connector lies in its ability to consolidate multiple connection requirements into a single, unified component. The eight available pins provide design engineers with a flexible platform to allocate specific pathways for different types of signals. It is common for several pins to be dedicated to delivering stable power to a component, while others are reserved for the high-fidelity transmission of data. This integrated approach allows for a more efficient use of space on a circuit board, reducing clutter and small the need for numerous individual wires and ports. The consolidation achieved with an 8 pin connector directly contributes to cleaner internal layouts, simplified manufacturing workflows, and enhanced overall system reliability by reducing potential points of failure.

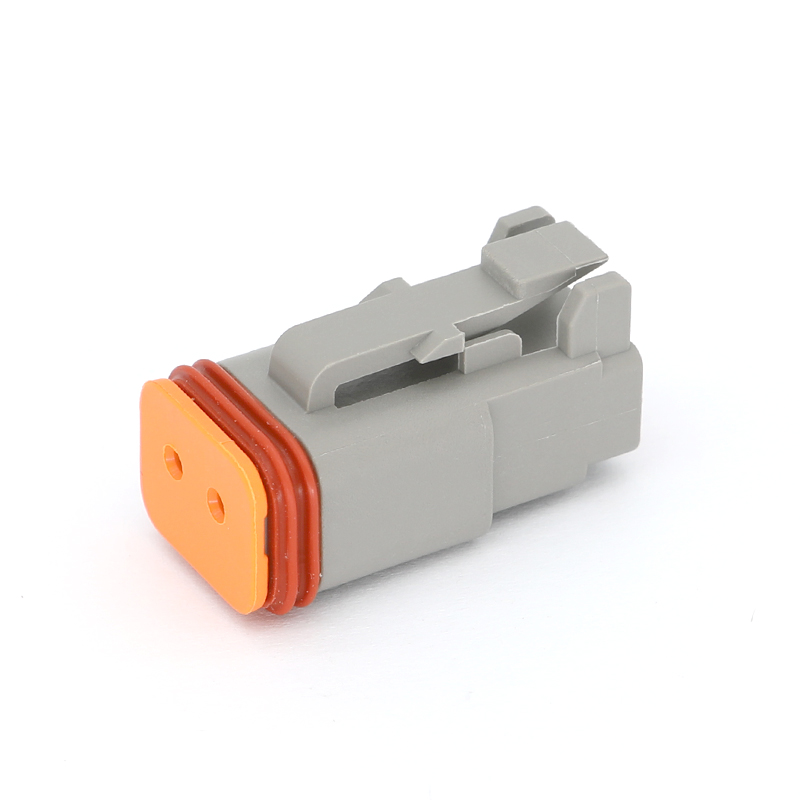

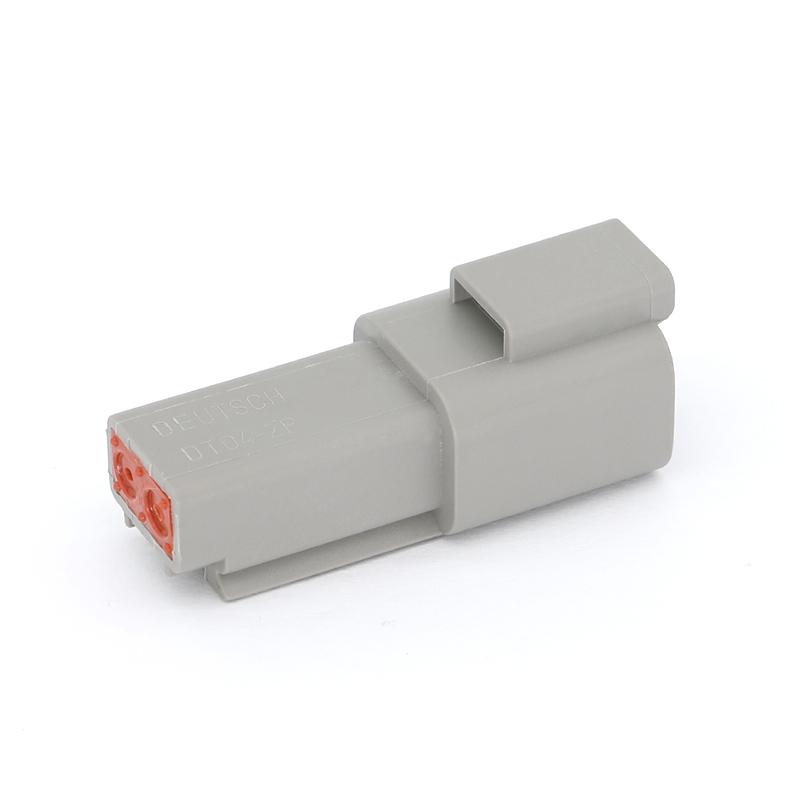

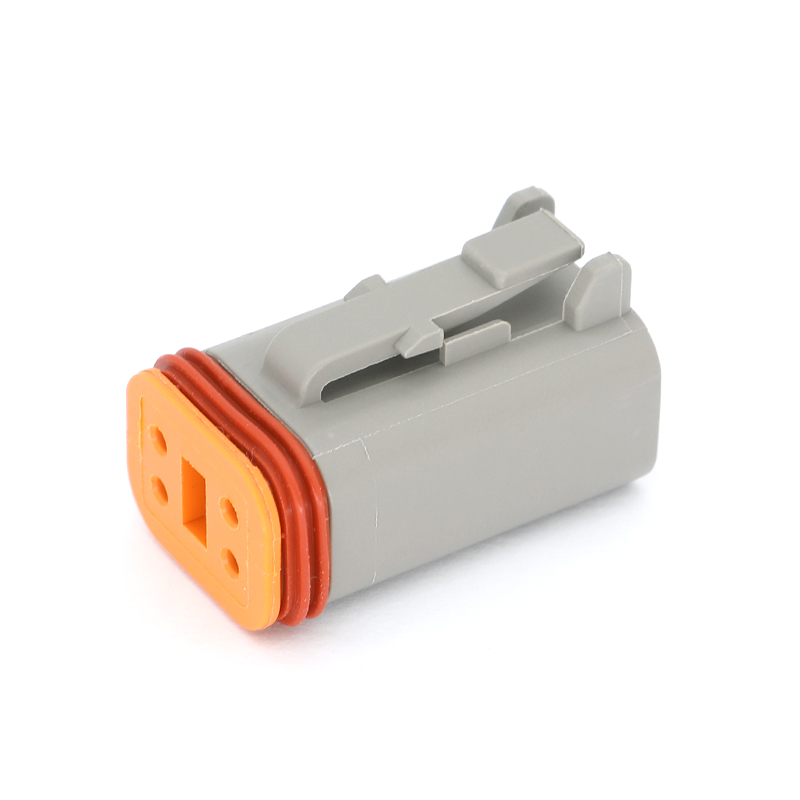

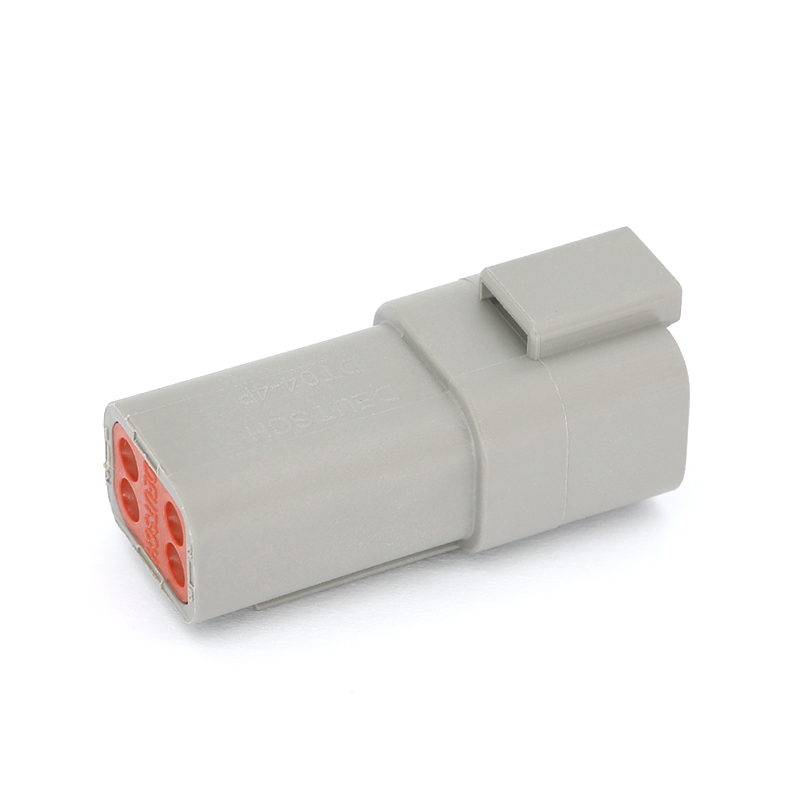

The physical construction of the 8 pin connector is engineered for long-term performance and durability. The outer housing is typically manufactured from high-grade, resilient thermoplastics that provide outstanding insulation against electrical shorts and robust protection from physical stress. Within this housing, the pins are precision-formed from conductive materials and often feature specialized plating to ensure ideal electrical contact, resist corrosion, and maintain signal integrity over thousands of mating cycles. Furthermore, many 8 pin connector designs incorporate secure locking mechanisms, such as latches or screws, which prevent unintended disconnection in environments subject to vibration or movement, a critical consideration for automotive and industrial applications.

The application scope for the 8 pin connector is remarkably broad, underscoring its inherent adaptability. In the realm of consumer technology, these connectors are frequently employed within computing hardware, external storage devices, and advanced peripheral equipment. The industrial sector relies on the 8 pin connector for use in machinery control systems, complex sensor networks, and communication modules where the simultaneous transfer of power and data is a fundamental requirement. The ongoing evolution of vehicle electronics also sees the 8 pin connector facilitating connections in enhanced infotainment units and other onboard control modules.

Looking ahead, the future for the 8 pin connector appears closely tied to the overarching trends of miniaturization and increased functional integration. As devices continue to become more powerful yet smaller, the pressure on internal space will only intensify. The 8 pin connector is poised to remain a relevant and widely used solution, offering a proven, cost-effective, and reliable method for managing a diverse set of electrical connections. Continuous refinements in materials and contact design will further improve its power delivery capabilities and data transmission speeds, ensuring that the 8 pin connector continues to serve as an indispensable component in the architecture of tomorrow's electronic innovations.

English

English русский

русский Español

Español عربى

عربى 简体中文

简体中文