6 Pin Motorcycle Connector Ensures Reliable Bike Performance

The reliability and functionality of a modern motorcycle's electrical system depend on a network of robust and secure connections. Among these, the 6 pin motorcycle connector has become an increasingly common component, enabling more complex electrical features and ensuring dependable performance in the demanding environment of motorcycle operation. This specific connector type represents a tailored solution, designed to meet the unique challenges of vibration, moisture, and temperature fluctuations encountered on the road.

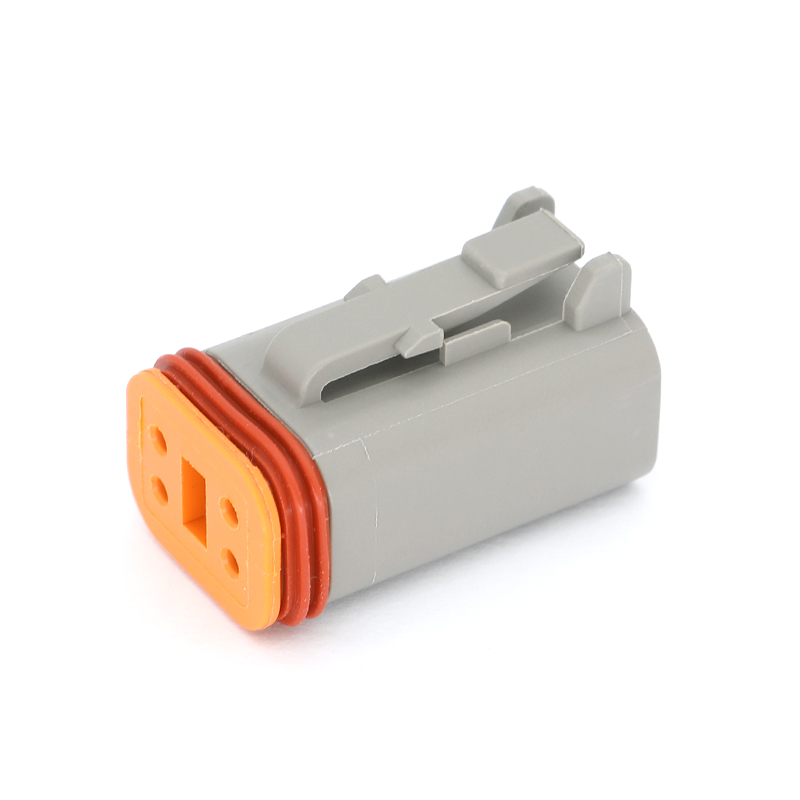

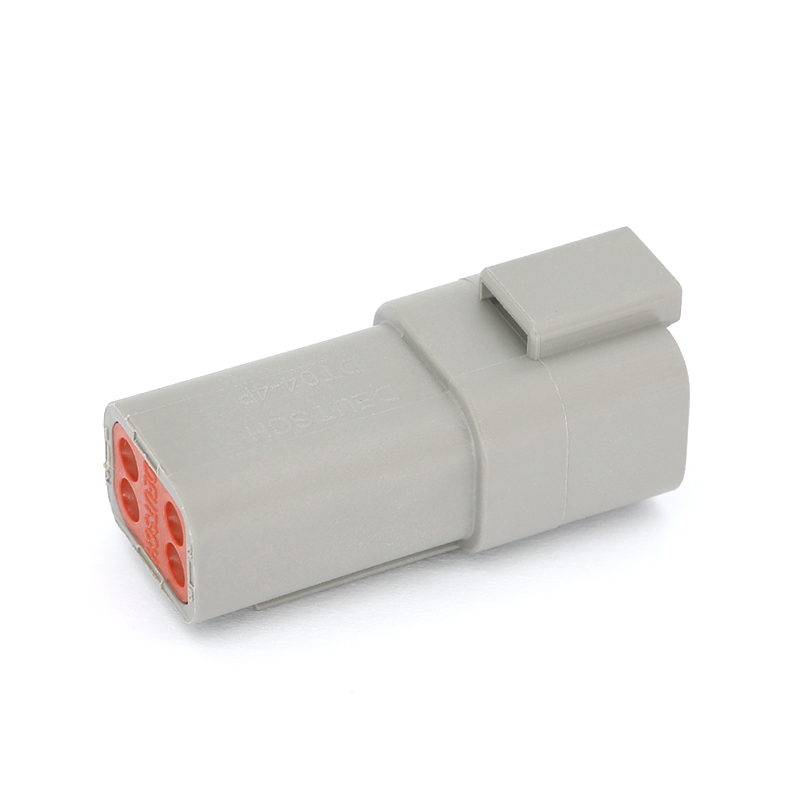

The primary role of a 6 pin motorcycle connector is to provide a consolidated and protected interface for multiple electrical circuits. The six pins within a single housing allow motorcycle manufacturers to streamline the wiring harness, connecting several functions through one plug rather than several individual ones. This design is crucial for managing the growing number of electronic features on contemporary motorcycles. A single 6 pin motorcycle connector might handle the combined functions for a handlebar control unit, integrating wires for accessories, lighting signals, and switch inputs. This consolidation significantly simplifies assembly during production and makes subsequent maintenance or repairs more straightforward for technicians, who can disconnect an entire component with a single action.

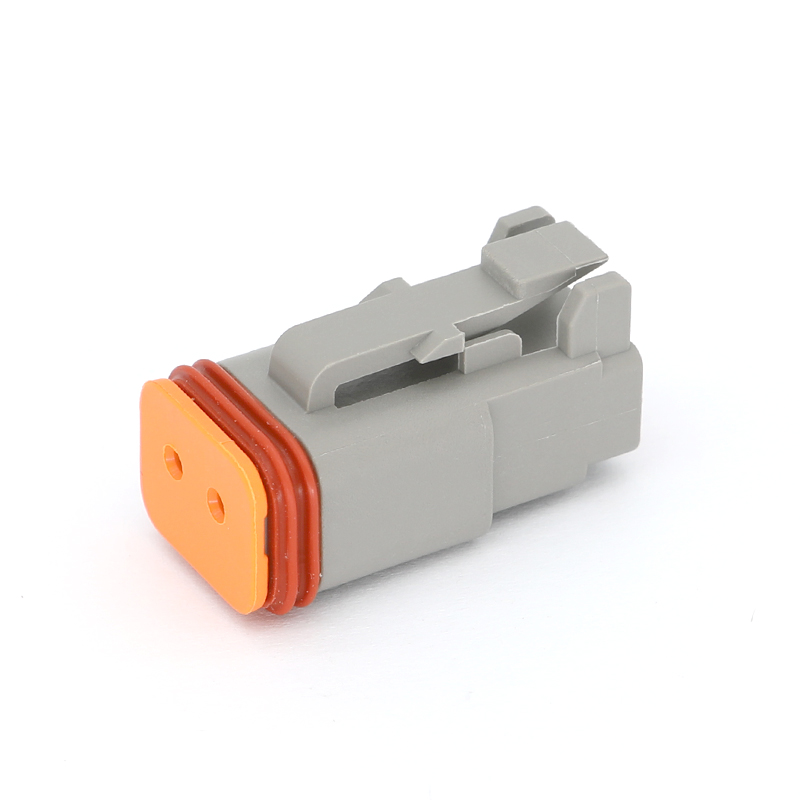

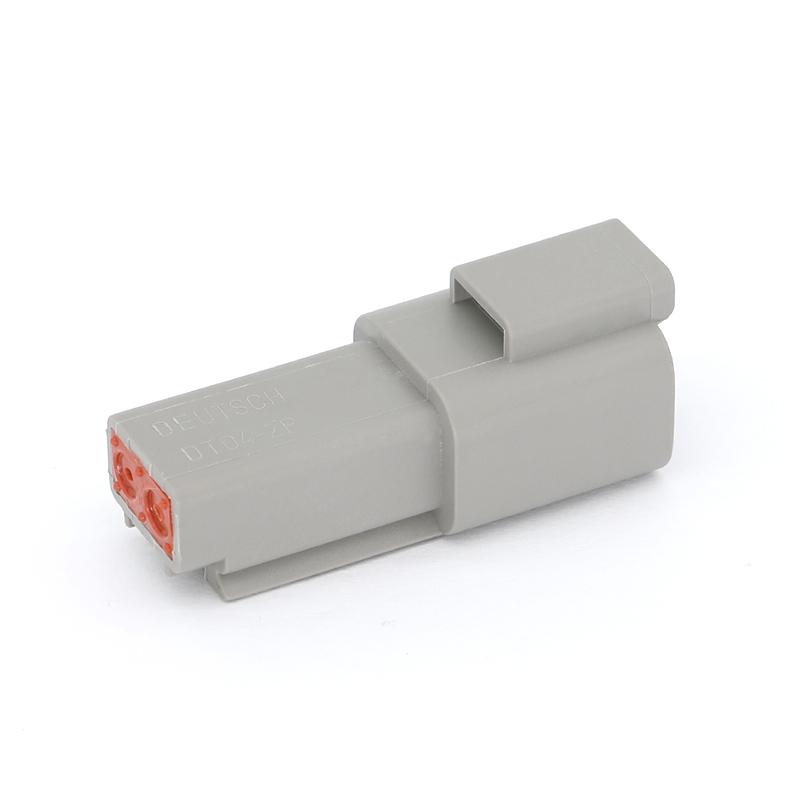

Durability is a non-negotiable requirement for any component on a motorcycle, and the 6 pin motorcycle connector is engineered specifically for this purpose. The housing is constructed from high-quality, impact-resistant thermoplastics capable of withstanding exposure to ultraviolet light, fuels, and cleaning agents. Crucially, these connectors are allots of always equipped with sealing gaskets and rubber seals at the mating interface and wire entrance, providing a high degree of protection against water and dust ingress. This IP-rated protection is essential for connectors located in areas exposed to spray from the wheels or direct rainfall. Furthermore, the metal terminals inside are designed with a secure locking tab or latch mechanism, ensuring the connection remains intact despite the constant vibrations experienced during riding.

The application of the 6 pin motorcycle connector is widespread across various motorcycle systems. It is frequently found linking the main wiring harness to the instrument cluster, which requires connections for power, ground, lighting, and data from various sensors. Another common use is in the connection between the motorcycle's frame and the rear tail section, which often houses the tail light, brake light, turn signals, and license plate lamp, all of which can be efficiently routed through a single 6 pin motorcycle connector. Its use is also seen in connecting advanced control units and sensor arrays that manage engine functions and rider aids, where reliable data transmission is as important as power delivery.

As motorcycle technology continues to advance, incorporating more sophisticated rider assistance systems and connectivity features, the demand for reliable multi-pin connectors will persist. The 6 pin motorcycle connector offers a balanced solution, providing sufficient circuit capacity for many applications without the excessive bulk of larger connectors. The ongoing development in this field focuses on enhancing the sealing capabilities, improving the chemical resistance of materials, and refining the terminal design for even greater longevity and electrical stability. The 6 pin motorcycle connector, therefore, remains a fundamental component in the electrical backbone of modern motorcycles, playing a key role in ensuring that electrical systems are as reliable and resilient as the machines they power.

English

English русский

русский Español

Español عربى

عربى 简体中文

简体中文