4 Pin Auto Connector Supports Advanced Vehicle Systems

As automotive electrical systems grow increasingly sophisticated, the demand for reliable, multi-circuit connections rises in parallel. The 4 Pin Auto Connector has emerged as a standardized and critical component within this evolving landscape, designed to facilitate more complex electrical interfaces than its simpler two-pin counterpart. This connector type provides four discrete pathways, allowing it to carry a combination of power, ground, and signal wires within a single, compact housing. Its adoption across various vehicle subsystems highlights its role in supporting advanced functionalities, from lighting control and sensor arrays to small motor units and electronic control module interfaces, making it a fundamental element in the architecture of contemporary automobiles.

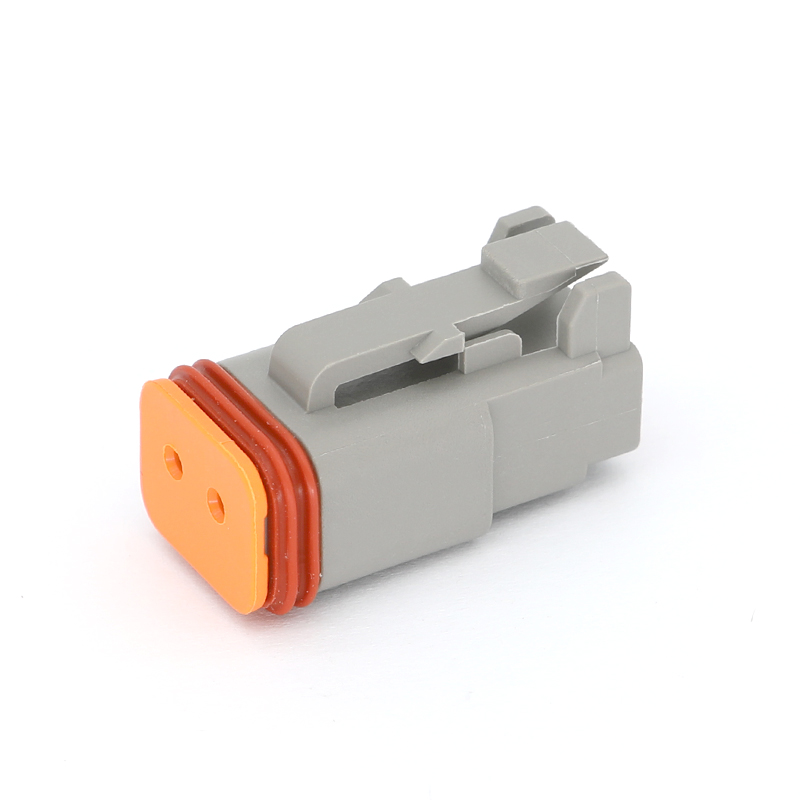

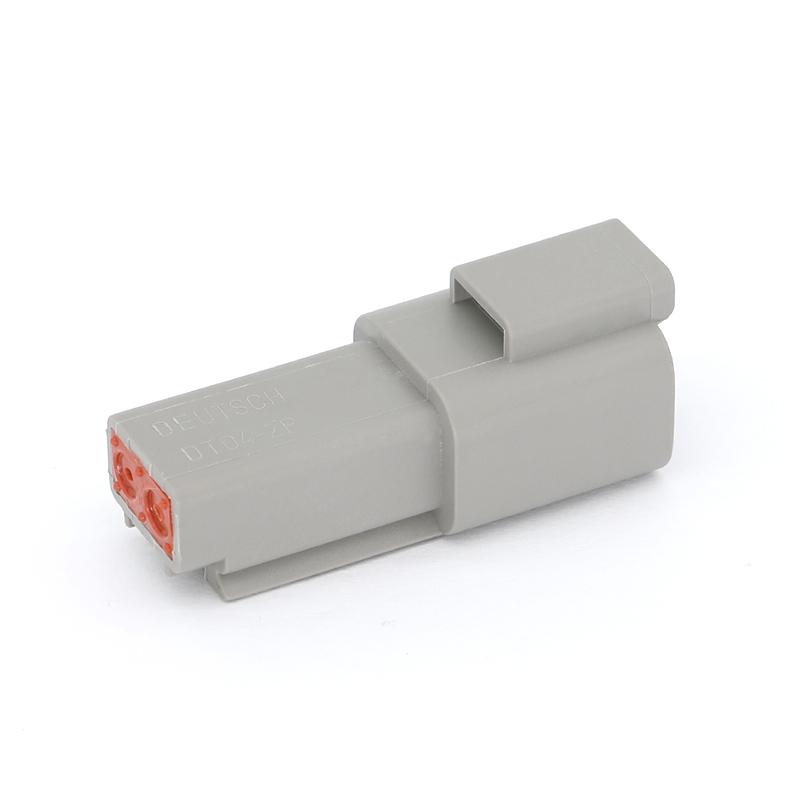

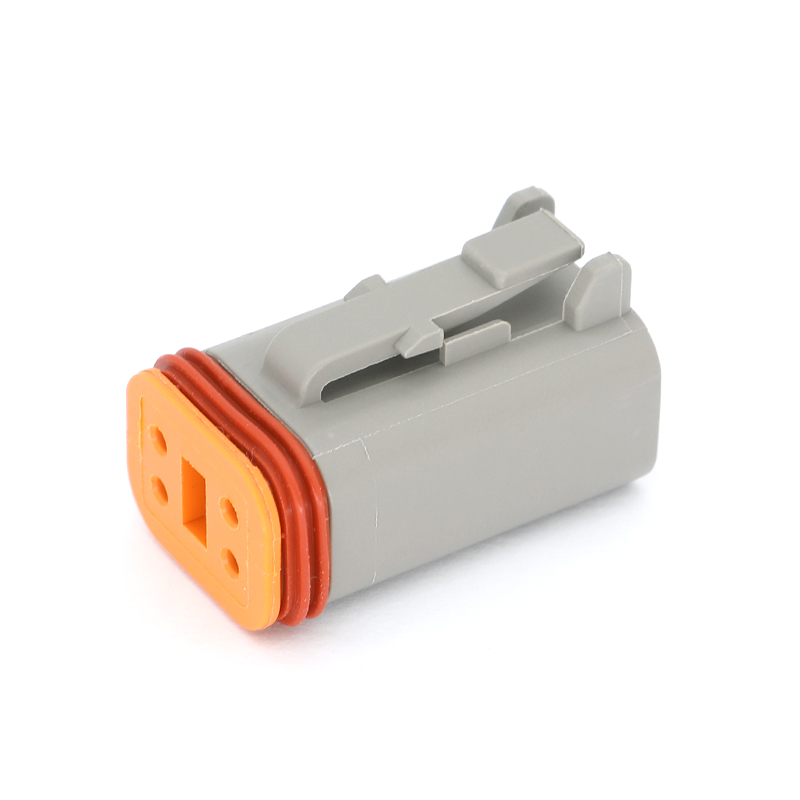

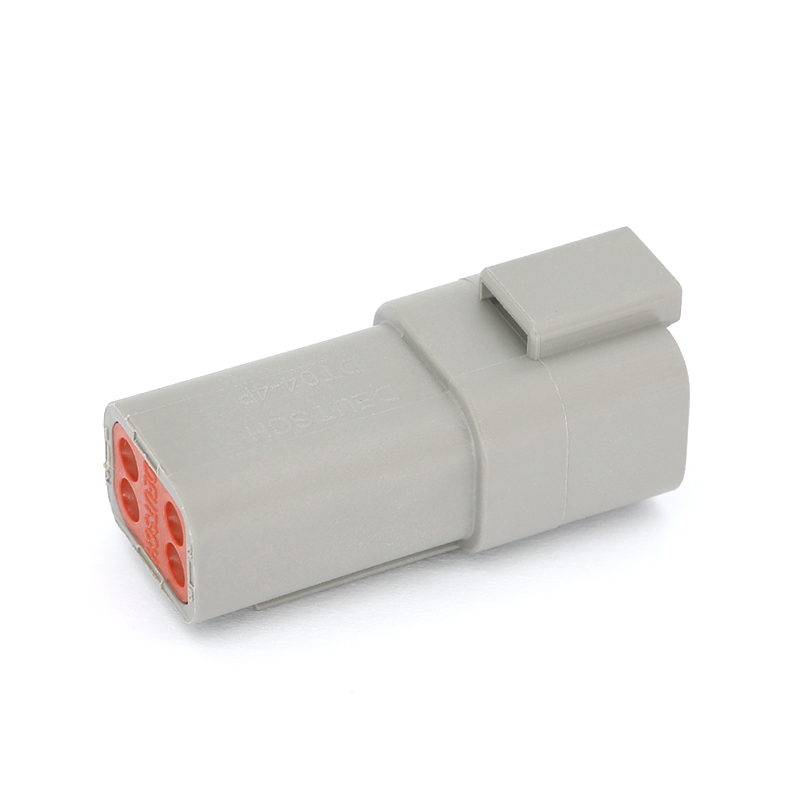

The design and construction of a robust 4 Pin Auto Connector are engineered to meet the rigorous demands of the automotive environment. The connector housing is typically molded from high-performance thermoplastics that offer resistance to high under-hood temperatures, automotive fluids, and prolonged UV exposure. Integral to its design is a secure locking mechanism—often a lever, latch, or audible-click tab system—that ensures a vibration-proof mating, preventing accidental disconnection that could cause system failure. Internally, the four terminal contacts are precision-stamped and formed from conductive metals like brass or copper alloy, frequently plated with tin or silver to ensure low electrical resistance and protect against corrosion. The terminals are designed to provide a stable, gas-tight connection when mated, which is essential for the reliable transmission of both analog sensor signals and digital data streams.

The functional versatility of the 4 Pin Auto Connector accounts for its widespread application. A common and highly visible use is in automotive lighting, particularly for headlamps and taillamps. In such an application, one 4 Pin Auto Connector can efficiently manage the multiple circuits required for low beam, high beam, daytime running lights, and turn signal functions, replacing several individual two-pin connections and simplifying harness design. Beyond lighting, these connectors are extensively used for sensors that require both power supply and signal return lines, such as wheel speed sensors for anti-lock braking systems (ABS) or position sensors.

The ongoing transformation of the automotive industry is influencing the development trajectory of components like the 4 Pin Auto Connector. The trend toward vehicle electrification necessitates connectors that can handle slightly higher currents for auxiliary systems in electric and hybrid vehicles while maintaining small voltage drop. The proliferation of Advanced Driver-Assistance Systems (ADAS) and in-vehicle networking requires connectors that support higher-frequency signals with improved shielding to prevent electromagnetic interference (EMI) from disrupting sensitive data. Consequently, newer iterations of the 4 Pin Auto Connector may incorporate more advanced shielding techniques, higher-temperature capable plastics, and seals that meet higher IP (Ingress Protection) ratings for use in exposed or wet locations.

The 4 Pin Auto Connector will continue to evolve as a vital interconnect solution, balancing the need for increased functionality with the constant requirements of durability, cost-effectiveness, and ease of assembly. Its design may see further miniaturization to save space and weight, alongside the integration of smart features such as embedded coding resistors or diagnostic pins for more sophisticated circuit monitoring. As vehicles become more integrated networks of electronic systems, the reliable performance of foundational components like the 4 Pin Auto Connector remains essential. It exemplifies how a standardized, multi-pin interface enables the complex communication and power distribution that underpin modern vehicle features, safety, and convenience, ensuring its continued relevance in next-generation automotive engineering.

English

English русский

русский Español

Español عربى

عربى 简体中文

简体中文