6 Pin Connector Serves Multiple Electronic Applications

Within the intricate world of electronic and electrical interconnection, the 6 Pin Connector continues to serve as a versatile and reliable interface across numerous industries. This component, designed to securely join six discrete electrical circuits within a single compact housing, balances sufficient pin density with physical manageability. The sustained relevance of the 6 Pin Connector highlights its utility in applications requiring a combination of power delivery, signal transmission, and ground connections through a standardized format.

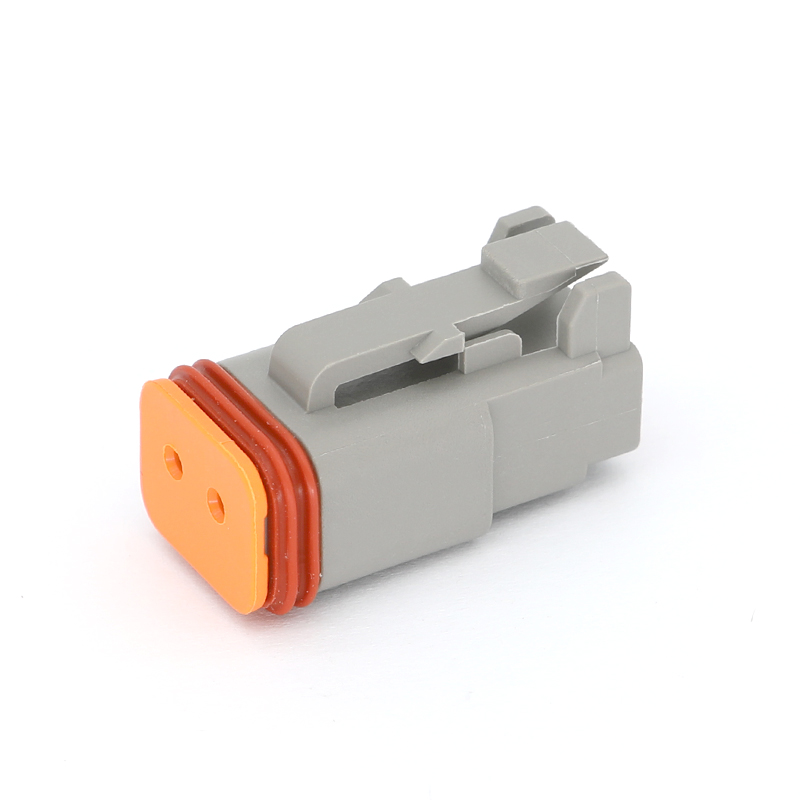

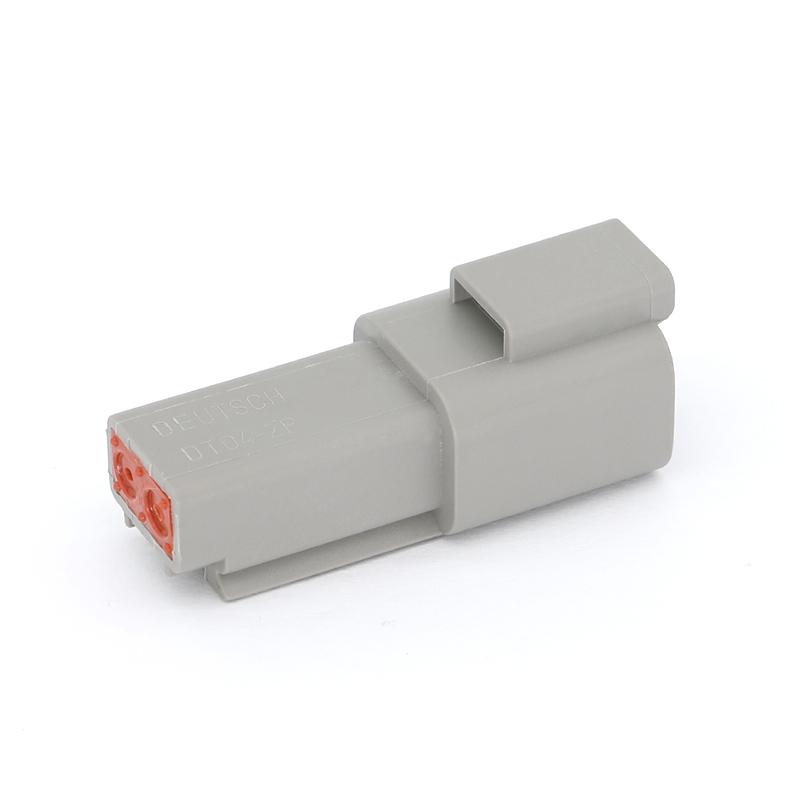

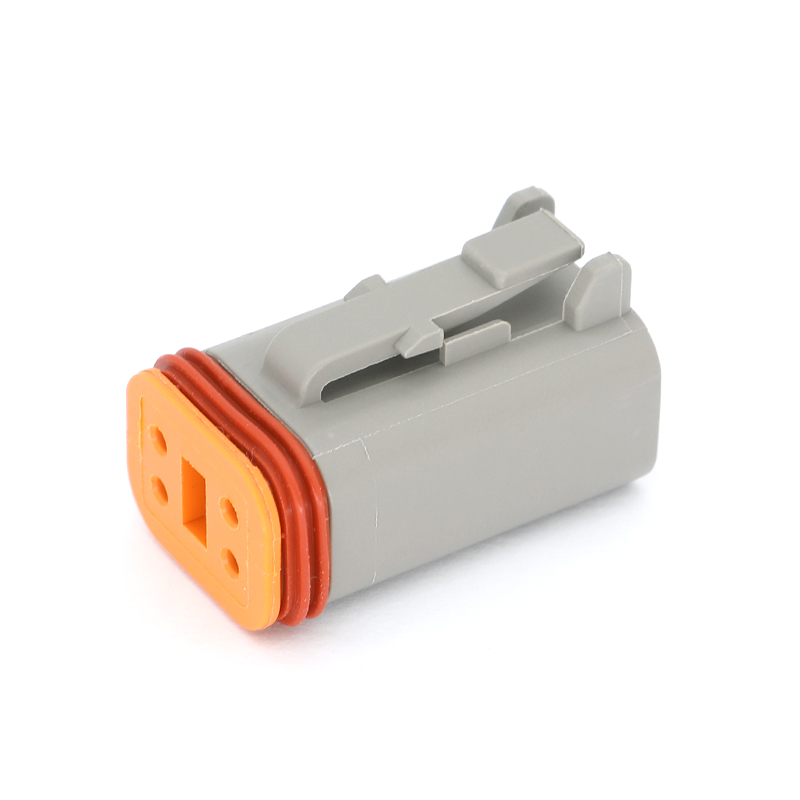

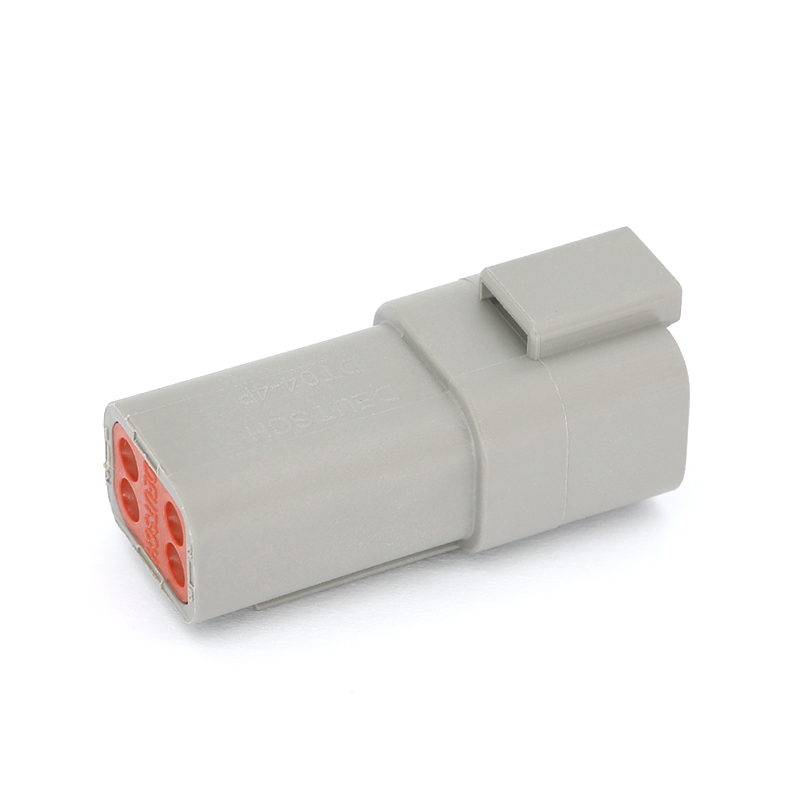

The fundamental design of a 6 Pin Connector focuses on creating a secure and consistent electrical pathway. Typically consisting of a male plug and a female receptacle, the connector houses six metal contacts, or pins. These pins are often arranged in a single row or two-row configuration and are crafted from conductive materials like brass or phosphor bronze, frequently plated with gold or tin for ideal conductivity and corrosion resistance. A robust housing, made from materials such as plastic or composite polymers, provides insulation and mechanical protection. A secure locking mechanism—ranging from simple friction fits and screw locks to more sophisticated latches—is a critical feature of a reliable 6 Pin Connector, preventing accidental disconnection in environments subject to vibration or movement.

The applications for a 6 Pin Connector are broad, reflecting its adaptability. In consumer electronics, it is commonly found in internal device cabling, connecting subsystems like power supplies to mainboards or linking displays to control units. Within industrial automation and machinery, the 6 Pin Connector is often employed for sensor connections, small motor controls, and interface panels, where it consolidates multiple control and feedback signals. The telecommunications and data hardware sectors also utilize the 6 Pin Connector for various equipment interfaces. Its configuration is particularly useful when a connection requires more circuits than a simpler 3 or 4-pin version can provide, but does not demand the higher density of larger, more complex connectors.

One of the key strengths of the 6 Pin Connector is its role in enabling modularity and serviceability. By using a standardized 6 Pin Connector, manufacturers allow for easier assembly, testing, and field replacement of components. A faulty module can be disconnected and swapped without the need to solder or rewire individual connections, saving time and reducing error. This plug-and-play functionality, facilitated by the 6 Pin Connector, is valuable in both manufacturing and maintenance contexts across many technical fields.

Performance specifications for a 6 Pin Connector are carefully defined based on its intended use. These include current and voltage ratings, operating temperature range, ingress protection (IP) rating for resistance to dust and moisture, and durability in terms of mating cycles. Selecting the correct 6 Pin Connector involves matching these specifications to the electrical requirements and environmental conditions of the application, ensuring long-term reliability and safety.

The 6 Pin Connector is expected to maintain its position as a workhorse component in the interconnect industry. Its simplicity, proven reliability, and ability to consolidate a practical number of circuits ensure its continued use in both legacy systems and new designs. As electronic systems become more pervasive, the fundamental need for dependable, medium-density interconnection—exemplified by the 6 Pin Connector—remains constant, securing its role in the foundational infrastructure of modern technology.

English

English русский

русский Español

Español عربى

عربى 简体中文

简体中文