8 Pin Connector Enables Advanced Device Integration

In the architecture of modern electronic devices and systems, the 8 Pin Connector has established itself as a significant interface for handling more complex electrical requirements. This component, designed to manage eight distinct circuits within a single compact unit, provides a balance between increased pin density and practical physical design. The widespread adoption of the 8 Pin Connector across various sectors underscores its utility in applications that demand a reliable combination of power, multiple data signals, and grounding paths.

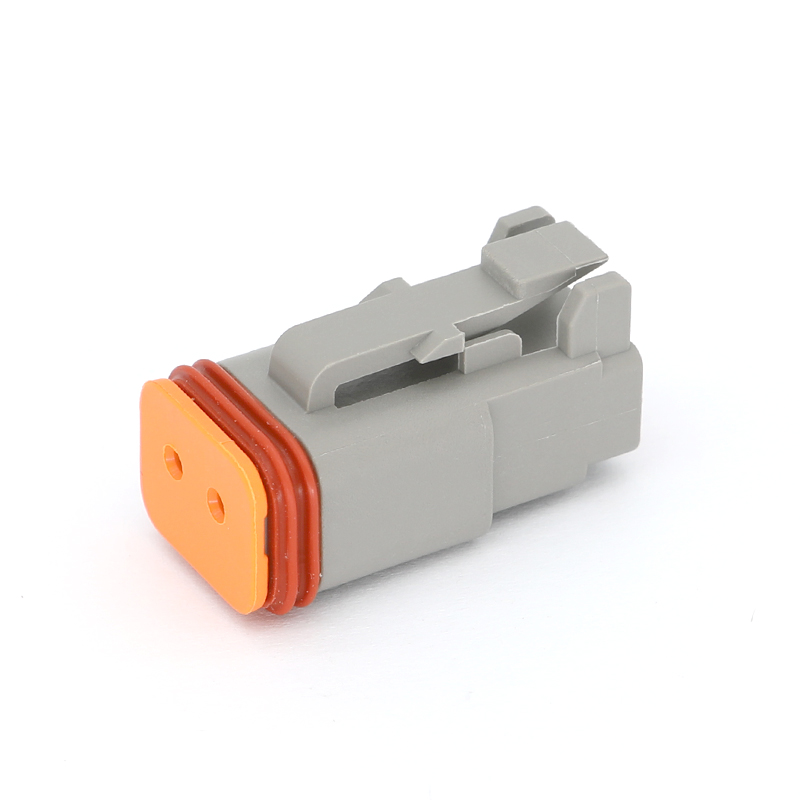

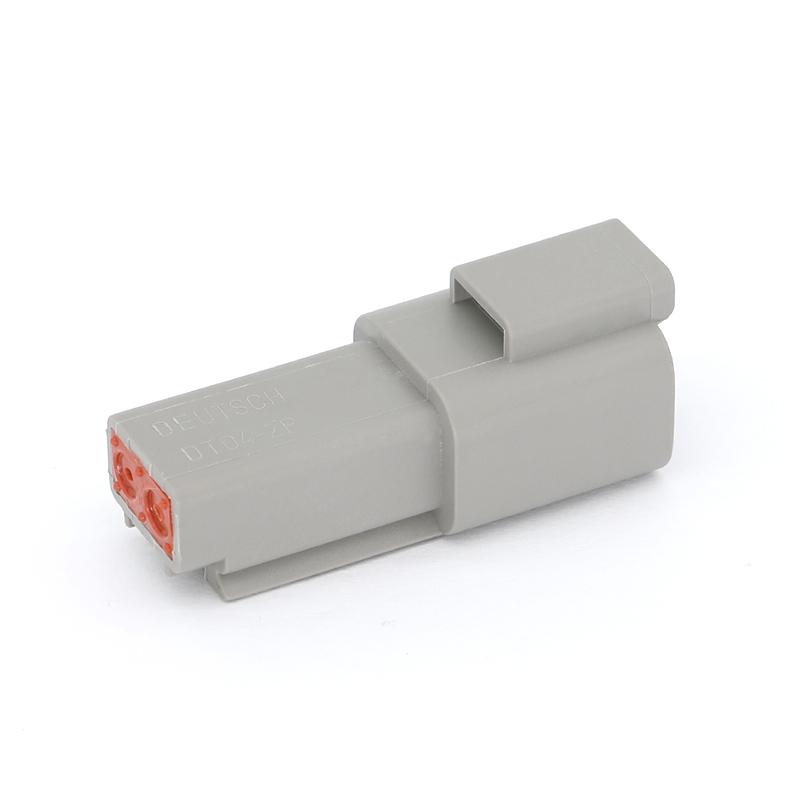

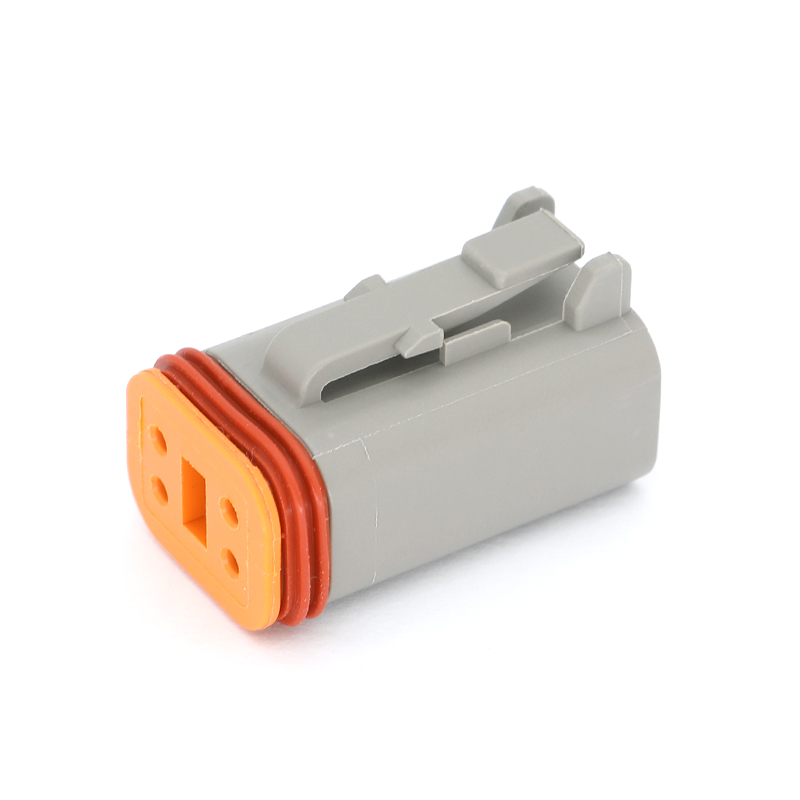

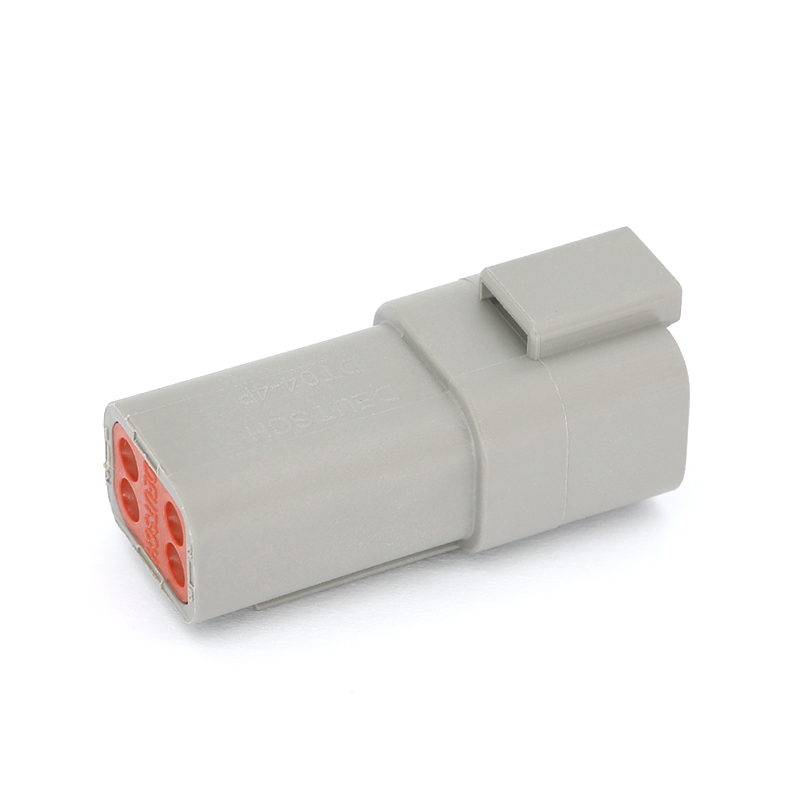

The typical 8 Pin Connector consists of a plug and receptacle pair, with eight conductive pins or sockets arranged in specific patterns, often in dual rows. These contacts are manufactured from materials like copper alloy and are frequently plated with gold or tin to ensure outstanding electrical conductivity, low contact resistance, and protection against oxidation. The housing, typically made from durable plastic or other insulating materials, provides structural integrity and protects the pins from physical damage and environmental factors. A secure locking mechanism is a standard and critical feature in an 8 Pin Connector, preventing unintended disconnection that could disrupt system operation, especially in mobile or high-vibration environments.

The application scope for an 8 Pin Connector is notably diverse. In computing and consumer electronics, it is a common sight, often used for internal power connections to motherboards, for linking external peripherals, or as a proprietary interface for specific device functions. The 8 Pin Connector is particularly prevalent in power supply units, where it delivers dedicated power to critical components like central processing units and graphics processing units, requiring multiple voltage and ground lines. Beyond computing, the 8 Pin Connector is utilized in industrial control systems, telecommunications equipment, medical devices, and professional audio/video gear, where it reliably manages power distribution and signal multiplexing.

One of the primary advantages offered by the 8 Pin Connector is its ability to consolidate multiple connections into one robust interface. This consolidation reduces cable clutter, simplifies the assembly process, and enhances overall system reliability by small the number of individual contact points prone to failure. The use of a standardized 8 Pin Connector also promotes modularity, allowing subsystems or components to be easily installed, upgraded, or replaced without requiring extensive rewiring. This plug-and-play capability, enabled by a well-designed 8 Pin Connector, is highly valued for maintenance and scalability in complex electronic assemblies.

Technical specifications for an 8 Pin Connector are carefully tailored to its intended use. Key parameters include current rating per pin, overall voltage rating, operating temperature range, and mating cycle durability. For applications involving data transmission, the connector's design must also consider signal integrity, managing crosstalk between adjacent pins. Selecting the appropriate 8 Pin Connector requires a thorough match between these electrical and mechanical specifications and the demands of the host system.

The 8 Pin Connector is poised to remain a fundamental component in electronic design. Its capacity to reliably manage a mid-range number of circuits makes it a versatile solution for an ever-widening array of sophisticated devices. As electronic systems grow more complex and integrated, the need for dependable, multi-circuit interconnection—exemplified by the 8 Pin Connector—will persist, ensuring its continued relevance in enabling the functionality and connectivity of future technologies.

English

English русский

русский Español

Español عربى

عربى 简体中文

简体中文