Are Automotive Connectors Worth It?

In the automotive industry, reliability and safety are paramount. Every component, from the engine to the small electrical connector, plays a crucial role in ensuring that vehicles operate efficiently and safely.

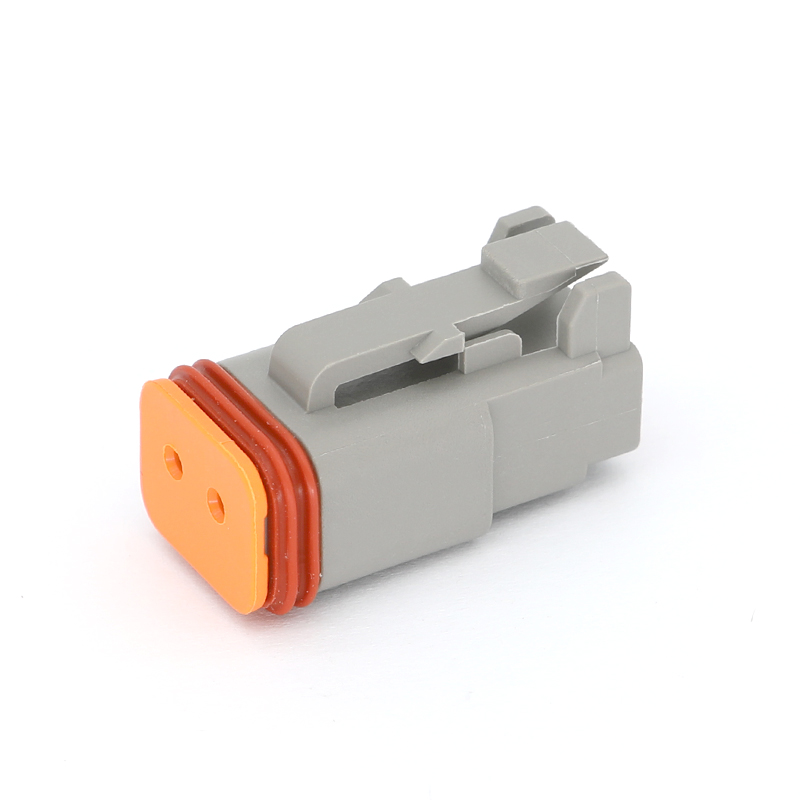

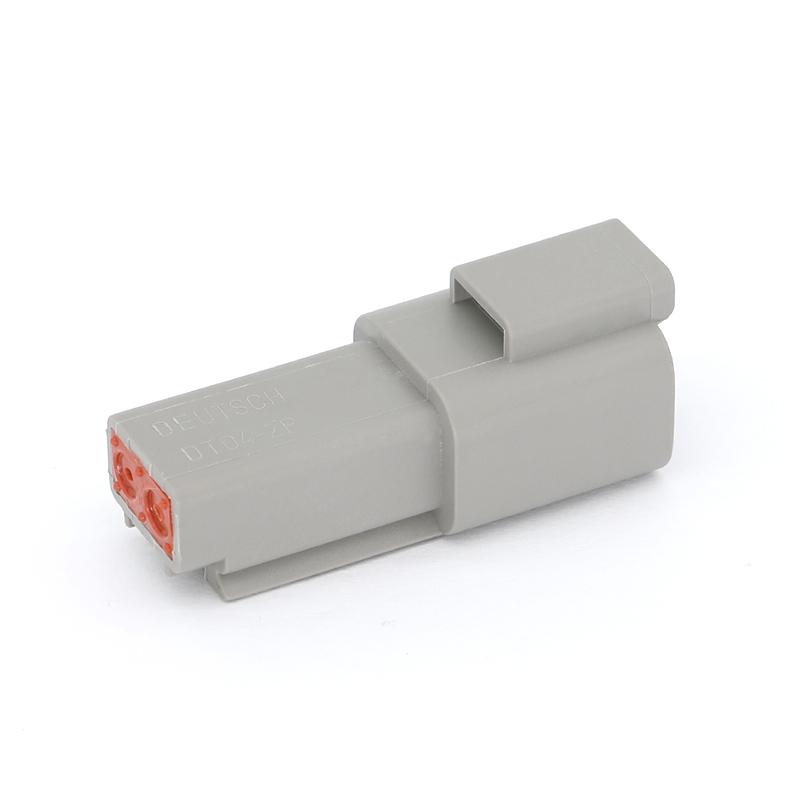

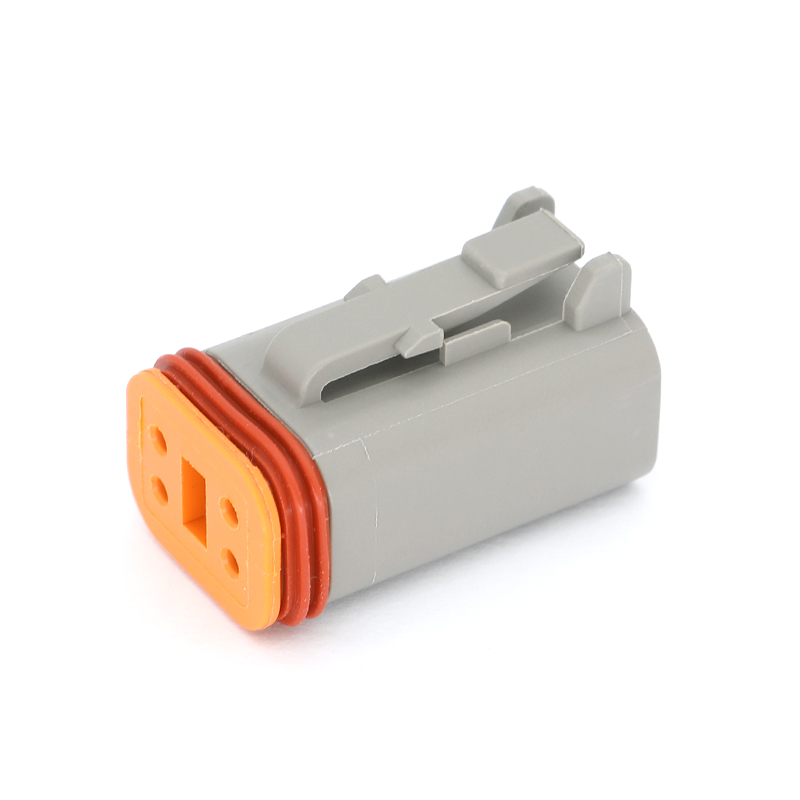

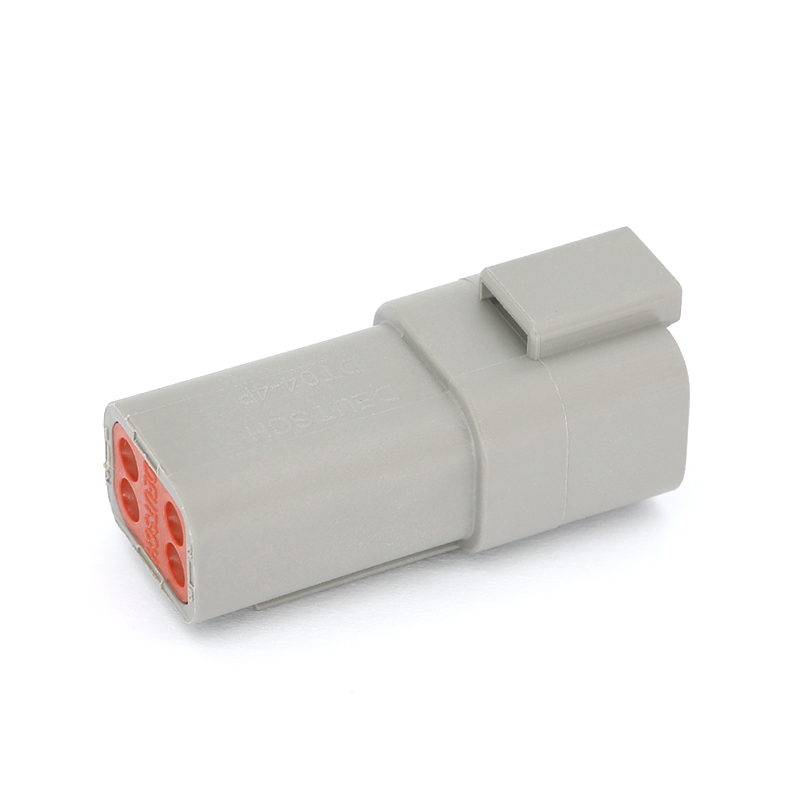

Automotive connectors are essential in the complex network of a vehicle's electrical system. These connectors facilitate the flow of electrical power and communication signals between various components, ensuring that everything from the headlights to the engine control unit operates seamlessly. In modern vehicles, which are increasingly reliant on electronic systems, the importance of these connectors cannot be overstated.

Automotive connectors must function reliably under a wide range of environmental conditions. Vehicles are exposed to extreme temperatures, humidity, vibration, and other harsh conditions. For instance, connectors in an engine bay might experience temperatures ranging from -40°C to over 125°C, while those in exterior lights must withstand rain, snow, and road debris. These challenging conditions demand connectors that are not only robust but also able to maintain their integrity and performance over the vehicle's lifespan.

To ensure reliability, automotive connectors undergo extensive testing. These tests simulate the conditions that connectors will face during their service life, including thermal cycling, vibration, mechanical shock, and exposure to corrosive environments. The USCAR2-7 specification, developed by the Society of Automotive Engineers (SAE) and the U.S. Automotive Research Council, provides guidelines for the performance and testing of automotive electrical connectors. Adherence to these standards ensures that connectors can withstand the demands of automotive applications.

Automotive manufacturers, such as Ford, Toyota, and General Motors, source components from a variety of suppliers. These manufacturers depend on their suppliers to deliver parts that meet stringent quality standards. This relationship is built on trust and rigorous quality assurance processes. For example, Toyota's market share allows it to impose strict quality control measures on its suppliers, ensuring that every component, including connectors, meets its high standards for reliability and performance.

To address the diverse needs of different applications, connectors are classified based on several variables, including current carrying capacity, environmental resistance, and mechanical durability. These classes help ensure that each connector is suited to its specific application, whether it’s a high-power connection in an electric vehicle's drivetrain or a low-power signal connection in the infotainment system. The component manufacturer defines these classes to provide clarity and assurance that each connector will perform as expected in its intended environment.

Failures in automotive connectors can have significant consequences. A faulty connector can lead to electrical malfunctions, which might result in vehicle breakdowns or safety hazards. In severe cases, such failures can trigger costly recalls, damaging a manufacturer's reputation and leading to financial losses. Thus, investing in high-quality, reliable connectors is not just about compliance with standards; it’s about ensuring the safety and satisfaction of end-users.

As automotive technology evolves, so do the requirements for electrical connectors. The rise of electric and autonomous vehicles has introduced new challenges and opportunities. Electric vehicles (EVs) require connectors that can handle high voltages and currents, while autonomous vehicles rely on a plethora of sensors and communication systems that depend on reliable connectors for accurate data transmission. This technological shift drives innovation in connector design, materials, and manufacturing processes.

High-quality automotive connectors also contribute to the economic and environmental sustainability of the automotive industry. Reliable connectors reduce the likelihood of repairs and replacements, lowering maintenance costs for vehicle owners. Additionally, they help improve the overall efficiency of vehicles by ensuring optimal performance of electrical systems, which can contribute to better fuel economy and reduced emissions.

English

English русский

русский Español

Español عربى

عربى 简体中文

简体中文