How to Design Wire Harness Connectors?

Seeing all the different types of applications for wire harnesses - telecom, medical, military, industrial, automotive, etc. - it's no surprise that wire harnesses are highly customized hardware in electrical systems. When our designers first sit down with a customer, we try to understand the entire application and the budget and time constraints that require careful project management.

The first step in selecting the harness connector for a custom harness includes looking at the location and environmental factors of the intended application. Wire harnesses are often behind-the-scenes operators, hanging inside the entire system to provide their critical support role. This can mean some very restricted locations where temperature, wear, humidity, and other variables can come into play.

Think about military applications. Our men and women in uniform need their gear to go to the environments on the planet and beyond and still work ly. This requires cable engineers to understand the environmental variables involved and assemble the components to meet, if not exceed the project's specifications.

Mitigating Interference

Considering the location, it is possible to identify the different types of interference that need to be protected. Interference comes in many different forms but is essentially designed to reduce the transmission of data, power, or signals. Effective mitigation techniques, such as the use of polyester film sheathing to counter electromagnetic interference (EMI) and radio frequency interference (RFI), help protect the signal and keep the flow clean. This is especially important when it comes to communications.

With high-tech communications equipment, our engineers must work to protect the system from many types of interference that would otherwise degrade the signal or even cause complete failure.

Precision measurements make for a better harness

Using the right connectors and terminals as part of a quality harness design helps ensure that the harness is strong, protected, and properly wired to provide the conditions for the system to do its job effectively. All lengths of wire, gauges, terminals, connections, sheathing, shielding, and insulation are carefully measured and considered in the harness design to make the efficient use of materials possible. This helps projects stay on time and budget during production.

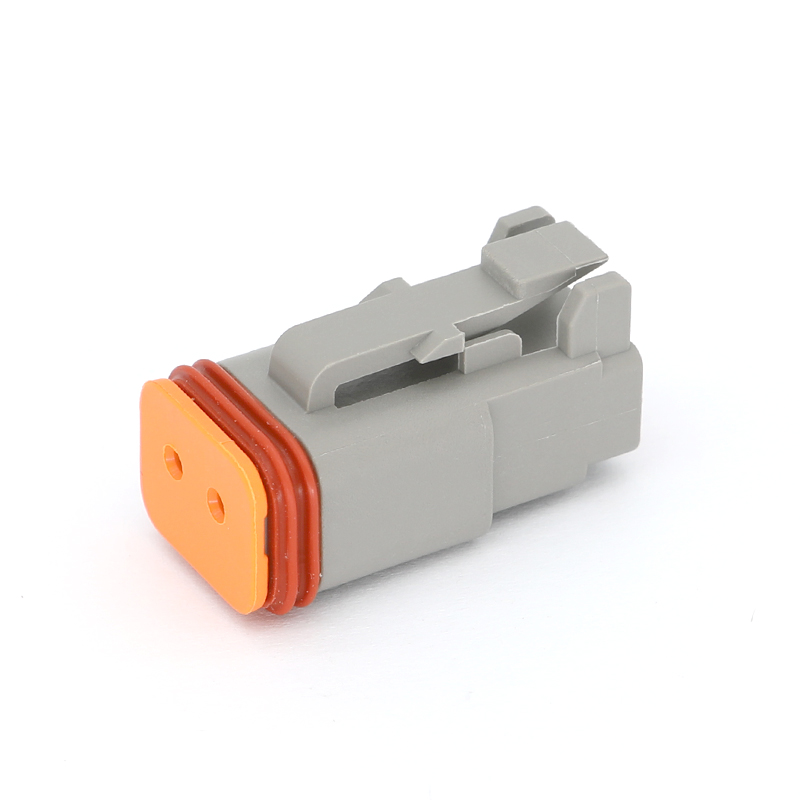

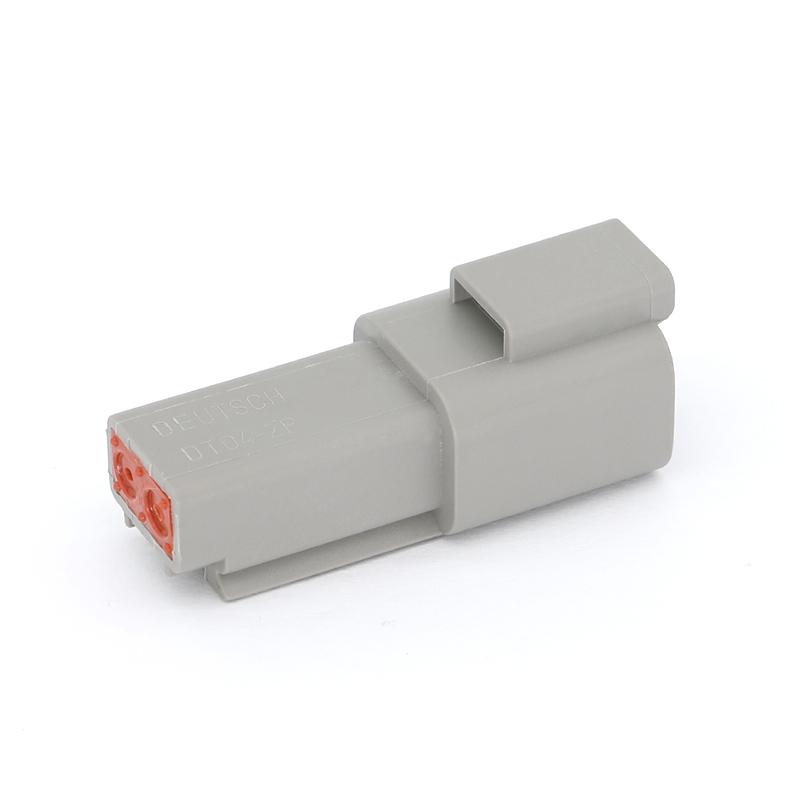

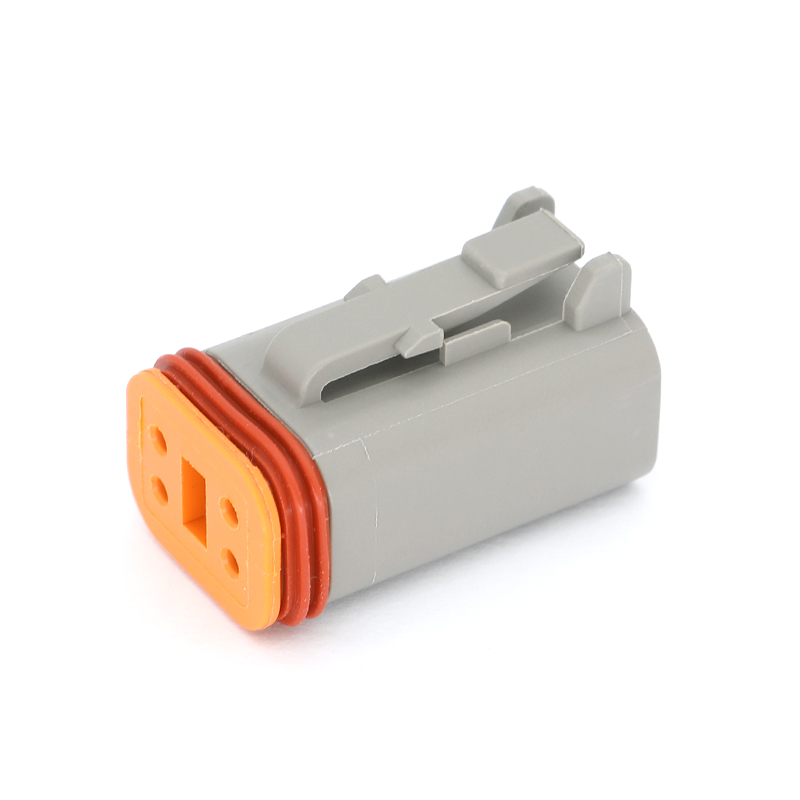

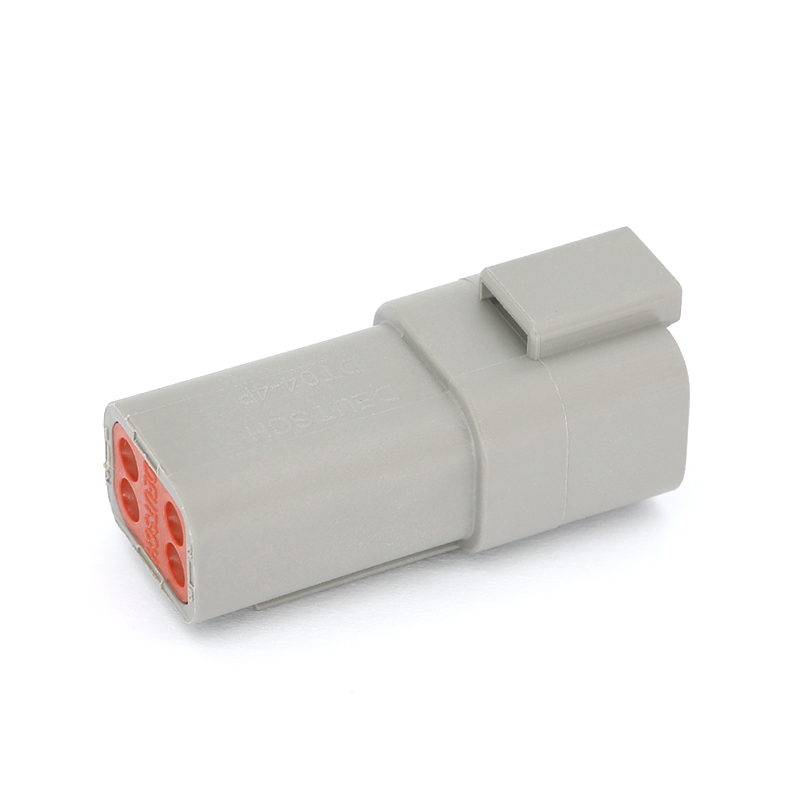

A Closer Look at Wiring Harness Terminals

Terminals are what they sound like—their termination of a wire. At this important junction, you might have the end of a wiring component or you may have a connector to a different component, it all depends on the needs of the system. Terminals come in a variety of sizes and shapes, as well, and are all pertinent to their particular application.

A few of the many different types of wire harness terminals include:

Rings: these terminals have a rounded end which lets them attach to screws and studs. Available in many different sizes, they can be insulated and crimped or soldered onto wires.

Spades – with a unique fork shape, these have an easily attachable open-end ideal for tight spaces.

Hooks – also with an open end, these are simple and efficient terminals with a high durability rating.

Quick-connect/disconnect – these are great for industrial control systems and automotive applications where the harness needs to be connected and disconnected rapidly.

Bullets – great for connections between male and female wire harness connectors.

Terminals play into the overall design of wire harness connections by providing the necessary junction from which a cabling harness can be terminated or progress to other components. Their design is just as crucial as any aspect of the custom wire harness to produce a product with the continuity, integrity, and safety required to pass our stringent in-house quality assurance testing.

English

English русский

русский Español

Español عربى

عربى 简体中文

简体中文