Auto Connectors: The Heroes of Modern Vehicle Electrical Systems

In the complex ecosystem of automotive engineering, auto connectors serve as vital components that keep vehicles running smoothly. These specialized electrical interfaces have become increasingly important as modern cars incorporate more electronic features, from advanced driver-assistance systems to sophisticated infotainment units. The evolution of auto connectors reflects the automotive industry's growing reliance on secure, high-performance electrical connections that can withstand demanding operating conditions.

The fundamental role of auto connectors in vehicle electrical systems cannot be overstated. These components create reliable pathways for power distribution and signal transmission between various electronic modules, sensors, and actuators. Modern vehicles may contain hundreds of auto connectors, each carefully designed for specific applications ranging from engine management systems to interior lighting. The precision engineering behind these connectors ensures consistent performance despite constant vibration, temperature fluctuations, and exposure to automotive fluids.

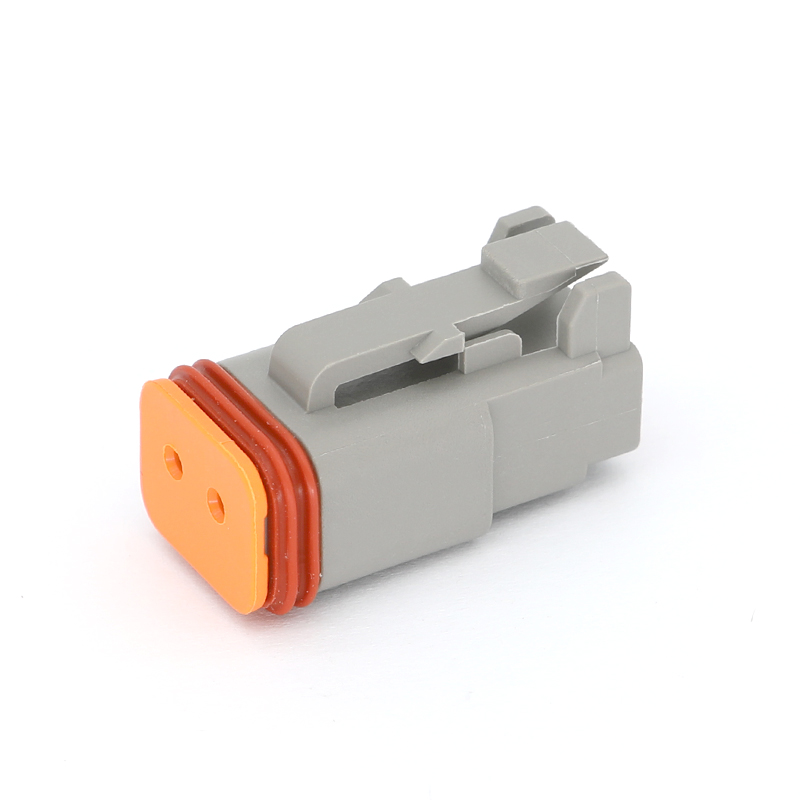

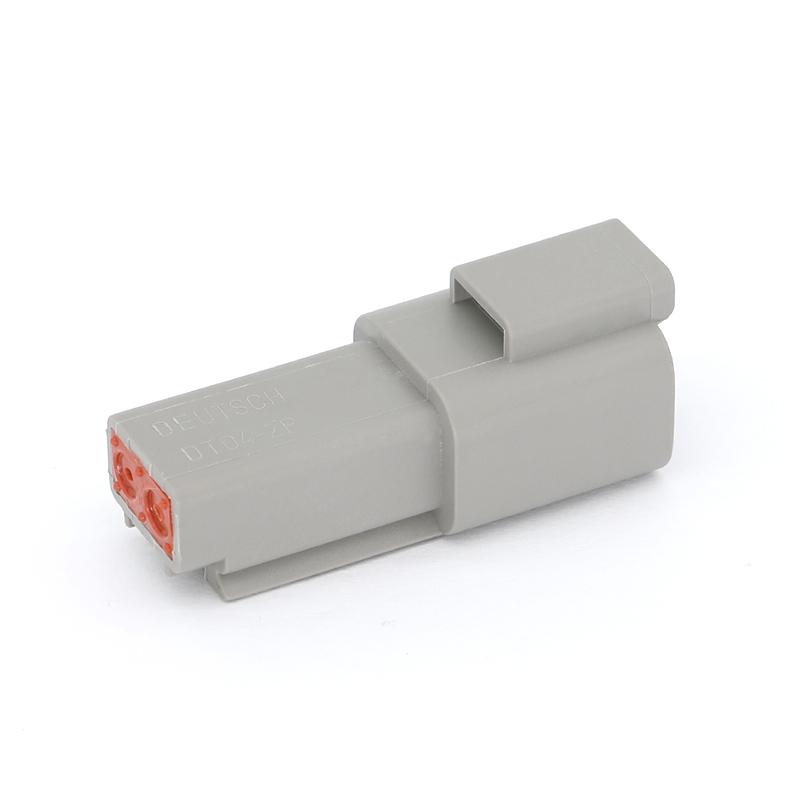

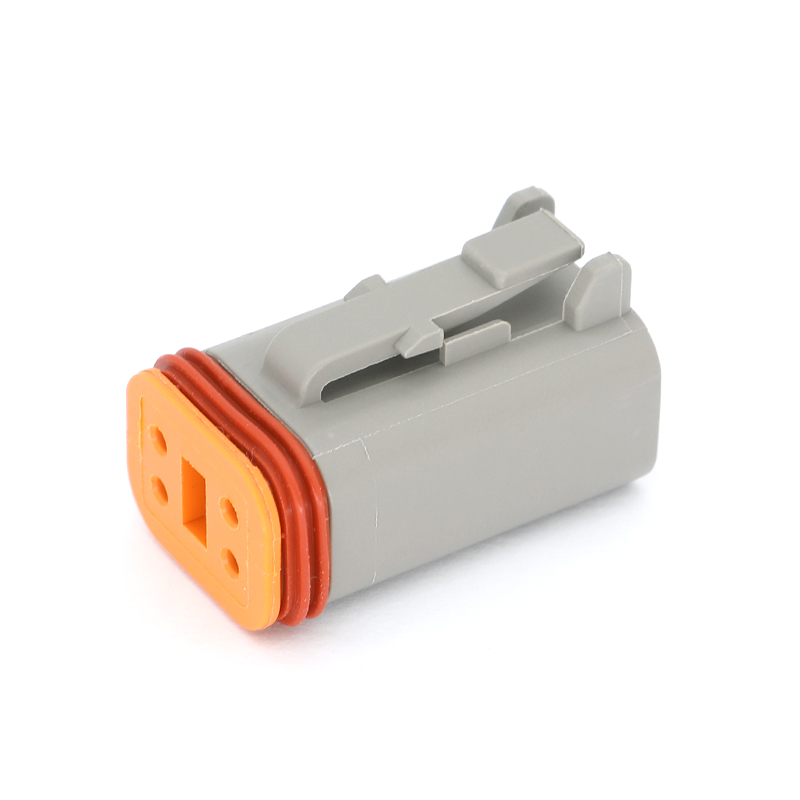

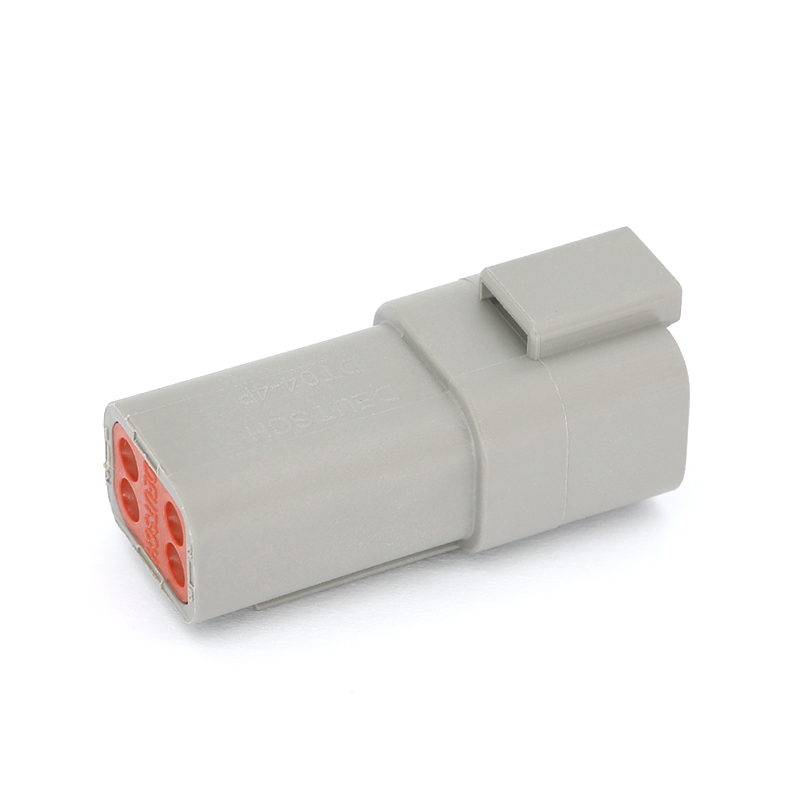

One of the lots of significant advancements in auto connector technology has been the development of waterproof and dustproof variants. As automotive electronics migrate to more exposed locations within vehicles, the demand for sealed auto connectors has grown substantially. These environmentally resistant connectors utilize specialized gaskets, seals, and housing designs to prevent moisture ingress—a critical feature for components located in wheel wells, undercarriages, or engine compartments. The improved durability of modern auto connectors directly contributes to vehicle reliability and reduced warranty claims.

The rise of electric vehicles has brought new challenges and opportunities for auto connector manufacturers. High-voltage applications require connectors with enhanced safety features, including sophisticated locking mechanisms and touch-proof designs. These specialized auto connectors must handle significantly greater electrical loads while maintaining absolute reliability. Simultaneously, the growing complexity of vehicle electrical architectures has increased demand for smart auto connectors with built-in diagnostic capabilities, allowing for easier troubleshooting and maintenance.

Standardization has become increasingly important in the auto connector industry. As vehicles incorporate more electronic content, manufacturers seek to reduce complexity by adopting common connector platforms across multiple vehicle lines. This trend toward standardization benefits both automakers and suppliers by simplifying inventory management and reducing development costs. Many modern auto connectors now follow international specifications, ensuring compatibility across different manufacturers and geographic markets.

The aftermarket sector represents another important application for auto connectors. Repair shops and vehicle owners frequently rely on replacement auto connectors to fix wiring issues or install aftermarket accessories. The availability of high-quality, application-specific auto connectors has made electrical repairs more accessible and reliable. This aftermarket demand has encouraged the development of connector kits that include all necessary components for common repair scenarios, from simple pigtail connectors to complete harness assemblies.

From basic wiring harness connections to sophisticated high-speed data links, auto connectors form the backbone of modern vehicle electrical systems. Their continuous evolution mirrors the rapid technological advancements in the automotive sector. As cars become more connected, electrified, and automated, the humble auto connector will continue to play an indispensable role in enabling these innovations—quietly ensuring that power flows and signals transmit exactly when and where they're needed. The future of automotive technology may be digital and wireless, but the physical connections provided by auto connectors will remain essential for years to come.

English

English русский

русский Español

Español عربى

عربى 简体中文

简体中文