Widespread Use of Auto Cable Connectors

As vehicles become increasingly sophisticated with advanced electronics and connectivity features, auto cable connectors have emerged as critical components ensuring reliable electrical performance. These specialized interfaces serve as the nervous system of modern automobiles, seamlessly connecting various electrical components while withstanding the harsh conditions of daily driving. The evolution of auto cable connectors reflects the automotive industry's growing need for durable, high-performance electrical solutions that can keep pace with technological advancements.

The importance of auto cable connectors becomes evident when considering their widespread use throughout vehicle architectures. From engine control units to infotainment systems, these connectors facilitate power distribution and data communication between critical components. Modern vehicles may incorporate hundreds of auto cable connectors, each meticulously engineered for specific applications. Their design prioritizes secure connections that resist vibration, moisture, and temperature bads—common challenges in automotive environments. This reliability is particularly crucial as vehicles incorporate more safety-critical electronic systems.

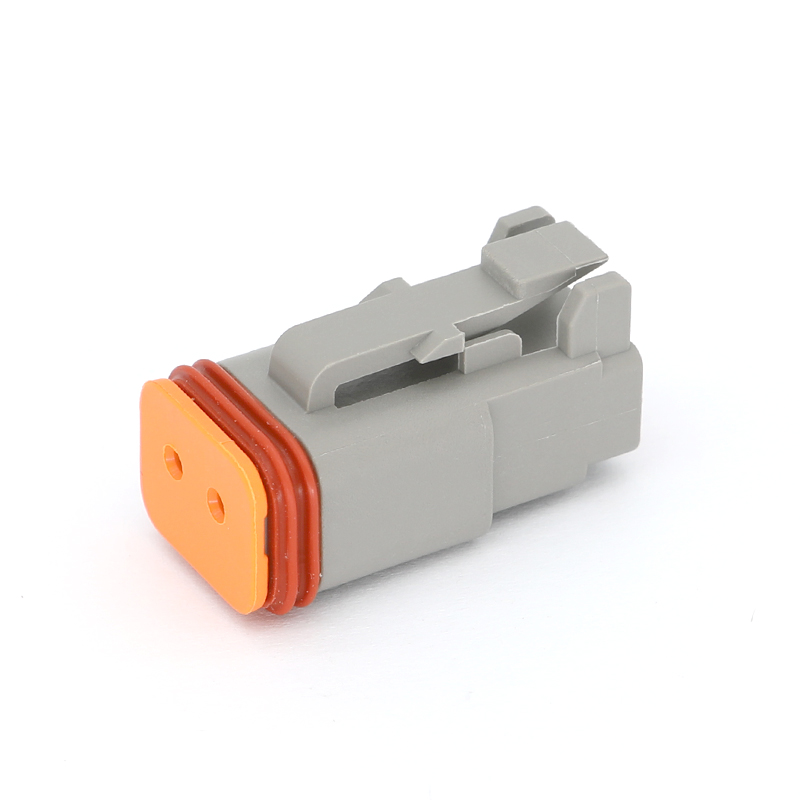

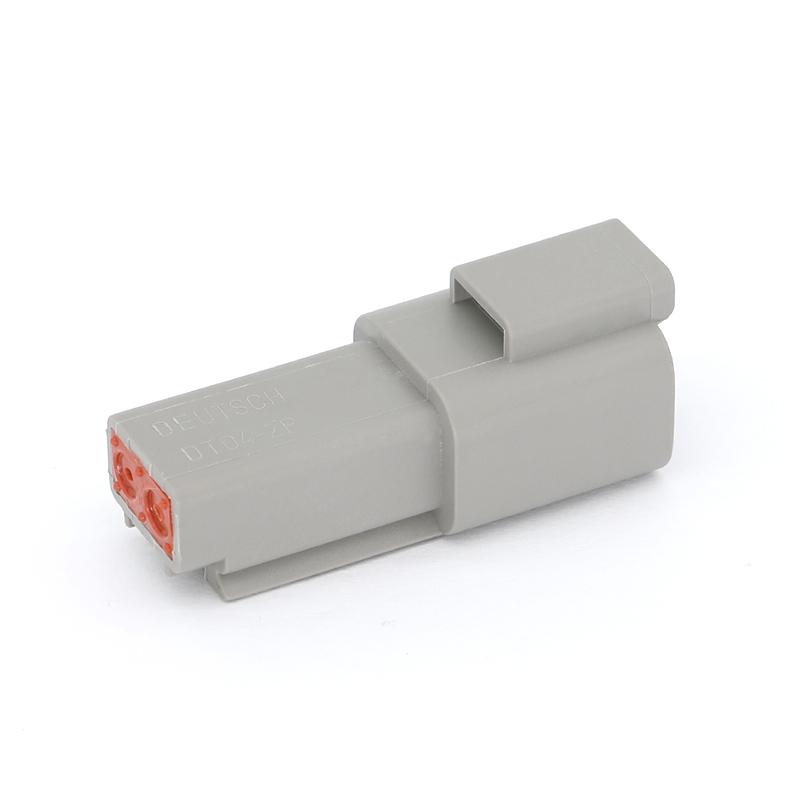

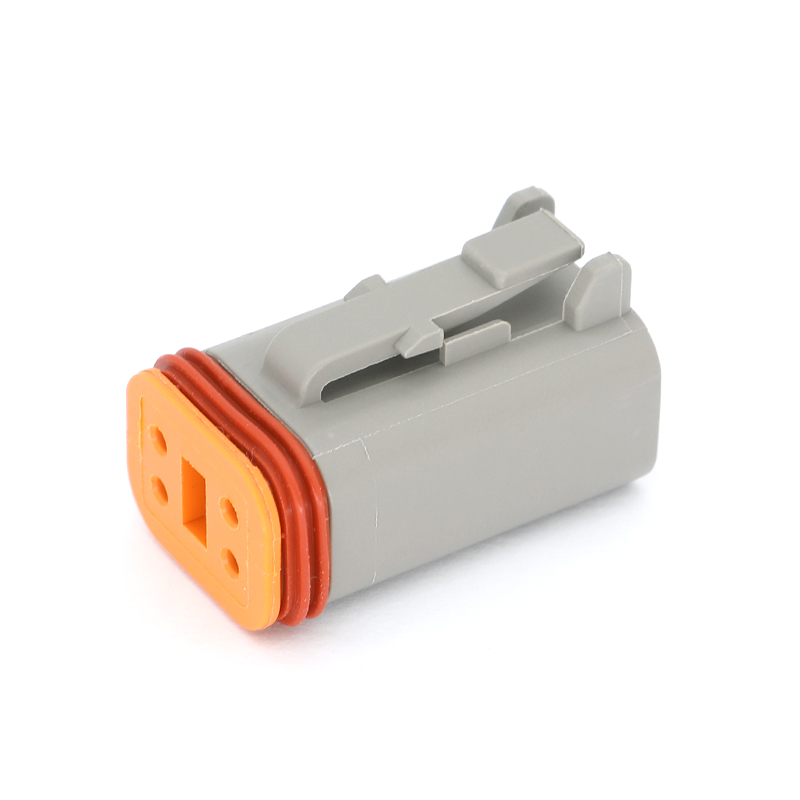

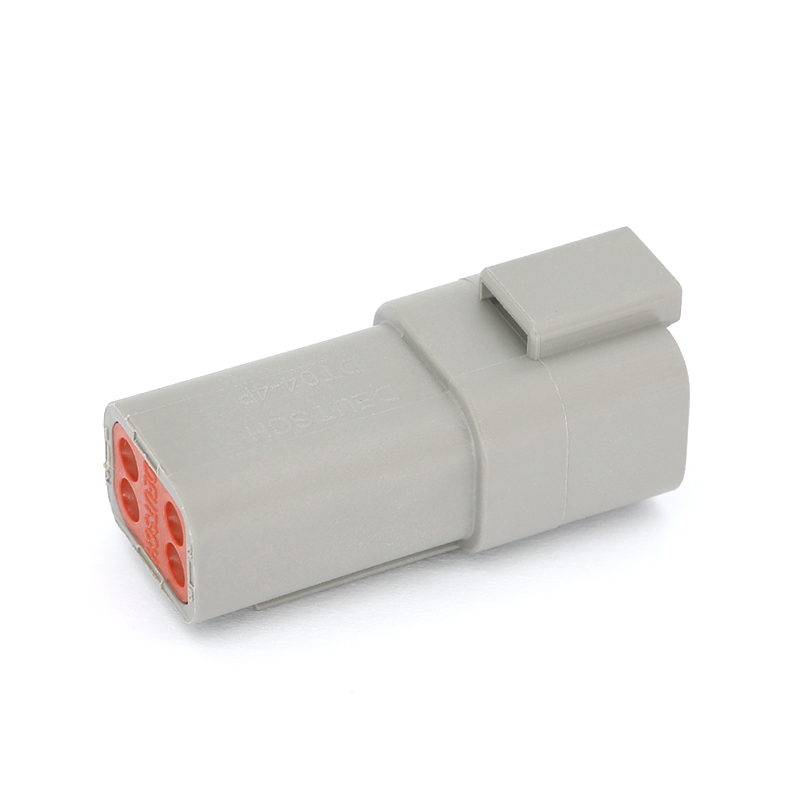

Recent advancements in auto cable connector technology have focused on improving durability and ease of installation. Many contemporary designs feature color-coded housings and intuitive locking mechanisms that reduce assembly errors during vehicle production. The development of sealed auto cable connectors has been particularly significant, offering protection against water ingress and contamination in exposed locations. These waterproof variants are increasingly common in electric vehicles where high-voltage systems demand additional safety considerations. The robust construction of modern auto cable connectors directly contributes to reduced warranty issues and improved long-term vehicle reliability.

The transition toward electrified mobility has created new opportunities for auto cable connector innovation. Hybrid and electric vehicles require specialized connectors capable of handling higher voltages while maintaining compact form factors. These high-voltage auto cable connectors incorporate advanced safety features such as interlock circuits and touch-proof designs to protect technicians during maintenance. Simultaneously, the growing complexity of vehicle electrical architectures has increased demand for auto cable connectors with integrated shielding to prevent electromagnetic interference in sensitive systems.

Material science innovations continue to enhance auto cable connector performance. New polymer compounds offer improved resistance to heat, chemicals, and mechanical stress, while advanced contact plating technologies ensure reliable conductivity over the vehicle's lifespan. These material advancements allow auto cable connectors to meet increasingly demanding automotive specifications without compromising on size or weight. The industry has also seen growing adoption of environmentally friendly materials in auto cable connector production, aligning with broader sustainability initiatives in automotive manufacturing.

Standardization has become a key trend in the auto cable connector industry as manufacturers seek to simplify supply chains and reduce costs. Many automakers now adopt common connector platforms across multiple vehicle lines, enabling economies of scale while maintaining performance requirements. This standardization benefits aftermarket repairs as well, with technicians having easier access to compatible replacement auto cable connectors. The development of universal connector systems has particularly helped streamline electrical system repairs and modifications.

From basic electrical connections to complex high-speed data networks, auto cable connectors remain fundamental to vehicle functionality. Their continuous development parallels the rapid technological progress in the automotive sector, ensuring they meet the demands of increasingly connected and electrified vehicles. As the industry moves toward software-defined vehicles and advanced mobility solutions, the physical connections provided by auto cable connectors will continue to serve as the essential infrastructure enabling these innovations. The future of automotive technology may be digital, but it will always depend on the physical reliability of auto cable connectors to deliver power and data where needed.

English

English русский

русский Español

Español عربى

عربى 简体中文

简体中文