Auto Connector Ensures Reliable Vehicle Electronics

The modern automobile is a complex network of electronic control units, sensors, actuators, and infotainment systems, all of which must communicate and receive power reliably. At the heart of this interconnected network lies a seemingly simple yet critically important component: the auto connector. These specialized electrical connectors are fundamental to vehicle assembly, functionality, and safety, serving as the secure interfaces that join wiring harnesses to every electronic device in a car, truck, or motorcycle.

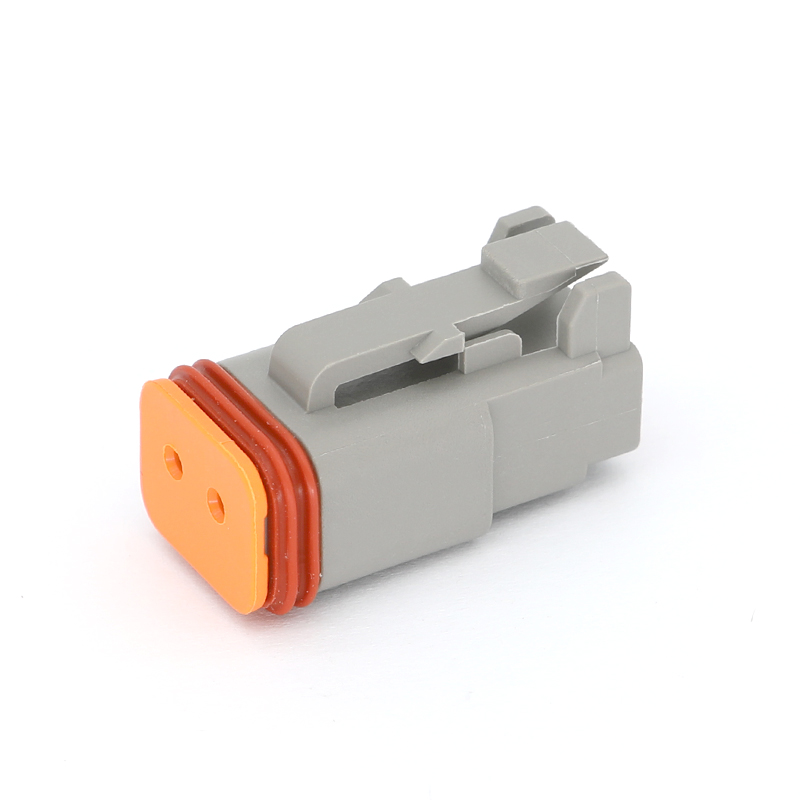

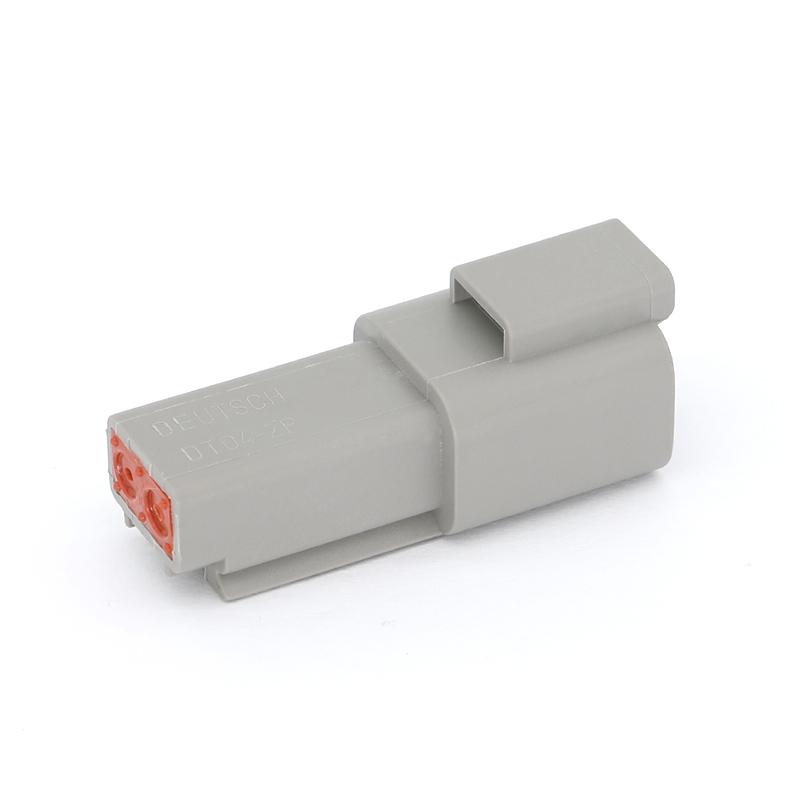

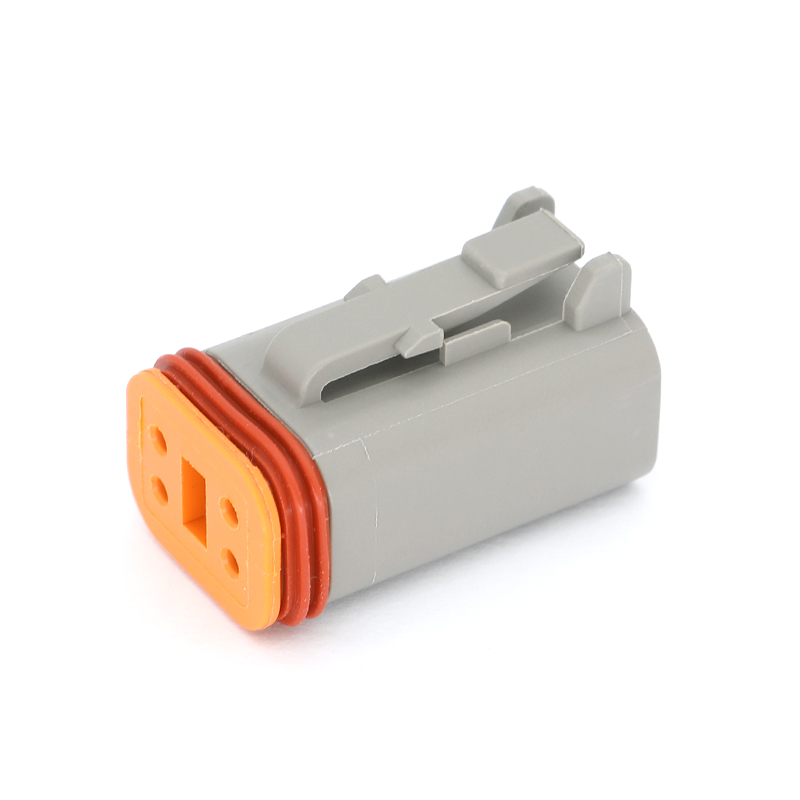

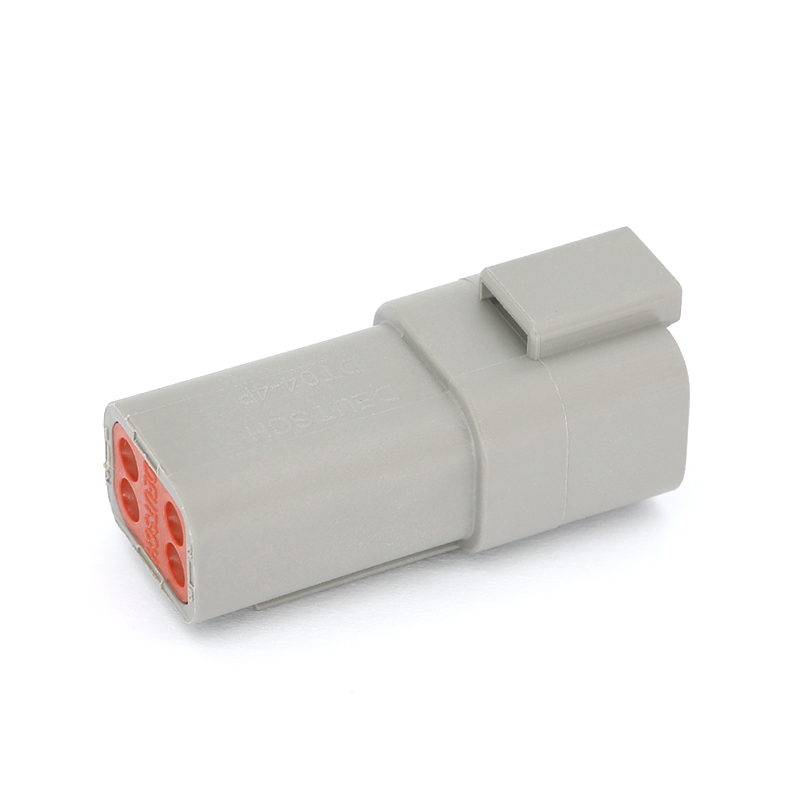

An auto connector is far more than a basic plug. It is an engineered system designed to withstand the unique challenges of the automotive environment. This includes constant vibration, bad temperature fluctuations, exposure to moisture, fuels, and chemicals. A typical auto connector consists of several key parts: a plastic housing, conductive terminals (pins and sockets), and a locking mechanism. The housing, often made from high-temperature thermoplastics, provides insulation and physical protection. The terminals, usually crafted from brass or copper alloys and plated with tin or gold, ensure stable electrical contact. The locking mechanism—whether a simple clip, latch, or screw—is crucial to prevent connections from loosening due to vibration, which could cause electrical failure.

The variety and specialization of the auto connector are immense, reflecting the diversity of automotive applications. From simple two-pin connectors for a door switch to complex multi-pin units with dozens of terminals for an engine control module, each auto connector is tailored to its specific role. Sealed connectors with rubber grommets and seals protect sensitive circuits in underhood and underbody locations from water and dust ingress. High-current auto connector versions are used for powertrain and battery connections, while smaller, precision types handle low-voltage signals for sensors and cameras. This specialization ensures that each auto connector meets the exact electrical, mechanical, and environmental demands of its location.

The importance of a reliable auto connector cannot be overstated in terms of vehicle safety and performance. A faulty connection can cause issues ranging from a non-functional infotainment screen to a complete loss of engine management data or failure of critical safety systems like airbags or anti-lock brakes. Therefore, the design, manufacturing, and quality testing of every auto connector follow stringent industry standards. These standards govern factors like insertion force, contact resistance, durability over mating cycles, and performance across a wide temperature range, from freezing cold to intense engine bay heat.

The evolution of vehicle technology directly drives innovation in auto connector design. The rise of electric and hybrid vehicles demands connectors capable of handling very high voltages and currents for battery and motor connections, with enhanced safety features to prevent arcing. Advanced driver-assistance systems (ADAS) rely on a growing number of cameras, radars, and LiDAR sensors, each requiring high-speed data auto connector types that can transmit large amounts of information without interference. This ongoing technological shift ensures that the auto connector sector remains a dynamic field focused on higher performance, miniaturization, and enhanced sealing.

The role of the auto connector will only become more central as vehicles evolve into increasingly software-defined and connected platforms. Trends like zonal electrical architectures and autonomous driving will require even more robust and intelligent interconnection solutions. The humble auto connector, by ensuring every electrical signal reaches its destination securely, will continue to be an indispensable enabler of automotive innovation, safety, and reliability, proving that the smallest components often bear the greatest responsibility in complex systems.

English

English русский

русский Español

Español عربى

عربى 简体中文

简体中文